How can intelligent monitoring improve the operational efficiency of sewage treatment plants and reduce energy consumption?

- release date: 2026-01-27 11:07:29

- author: Hongtai Huairui

- Reading: 712

- key words: Intelligent Monitoring、Wastewater Treatment Plant、WWTP、Intelligent Wastewater Treatment Plant、IWWTP、Intelligent Surveillance and Control、Smart Wastewater Treatment Plant、

Friends working in wastewater treatment plants are likely to have experienced this kind of anxiety: staying up all night in the control room during heavy rain to prevent overflow, running around the entire plant to measure DO levels for adjusting aeration parameters, legs so sore they can’t move, and even with meticulous planning, the energy consumption and cost per ton of water remain high. But now, this "experience-based, labor-intensive" type of operation and maintenance is being completely disrupted by intelligent monitoring technology. The United Nations SDG6.3 target clearly states that by 2030, the proportion of untreated wastewater globally must be halved. According to the IEA, wastewater treatment accounts for a quarter of the water sector's electricity consumption, and by 2030, energy consumption per unit must be reduced by 15%-20%, and carbon emissions intensity by 12%-18%. Driven by stricter environmental regulations and rising costs, intelligent monitoring is no longer exclusive to large wastewater plants in Europe and the U.S., but has become the core path for wastewater plants worldwide to break through.

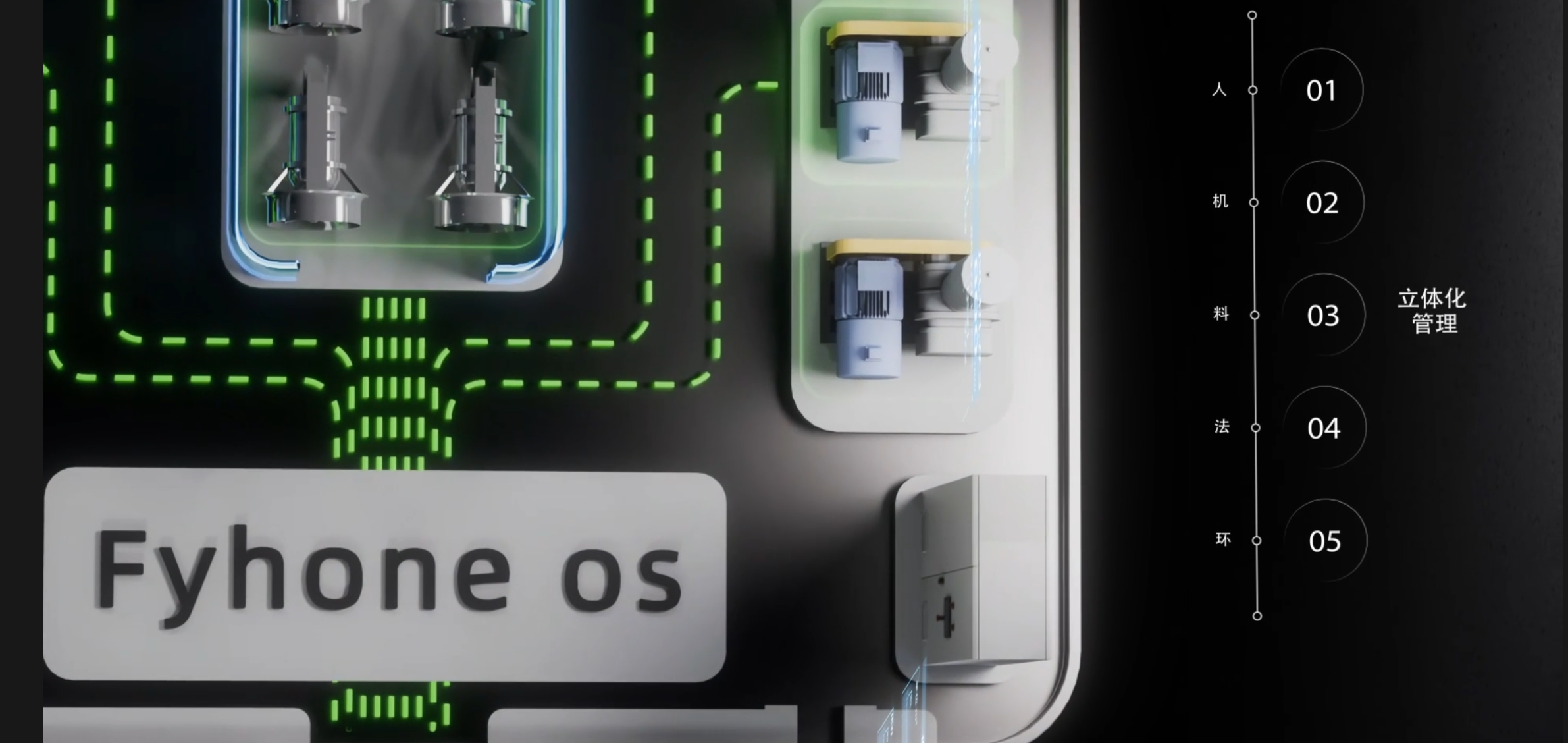

Many people mistakenly believe that intelligent monitoring is just "automation + remote viewing," but it is much more than that. It is a complete closed loop of "sensing - analyzing - decision-making - execution," with the core goal of replacing human experience with data to achieve 24/7 autonomous regulation, essentially giving the wastewater plant a tireless "smart brain." Its core architecture is very clear: front-end sensors collect key data such as COD and ammonia nitrogen every minute, with an accuracy rate of over 95%; mid-end AI algorithms can predict water quality fluctuations 12-48 hours in advance, with an accuracy rate of over 88%; back-end automation devices respond and regulate in milliseconds. This technology has already been implemented in over 1,000 wastewater plants globally. In simple terms, traditional operations are "human-controlled," while intelligent monitoring is "system-autonomous regulation," which is the key to reducing costs and improving efficiency.

Fluctuations in water quality are the number one challenge in operations and maintenance. The traditional model can only offer post-event remedies, often leading to environmental penalties. In contrast, intelligent monitoring relies on "real-time monitoring + early prediction," which can completely alleviate this anxiety. The system can sense changes in water quality in advance and dynamically adjust parameters like aeration volume and DO concentration. Data shows that untreated wastewater treatment plants typically have an effluent compliance rate of 85%-95%, but after renovation, this can rise to 96%-99.9%. COD fluctuations are reduced from ±12mg/L to ±3mg/L. After renovation, a European plant saved over 80,000 euros annually in chemical costs, while a Shenzhen MBR wastewater plant achieved DO control precision within ±0.5mg/L, significantly improving compliance rates.

Energy consumption is another tricky issue. Electricity costs account for 40%-70% of the energy costs in wastewater treatment plants, with aeration systems contributing 45%-70% of that. Under traditional operations, about 60% of wastewater plants worldwide suffer from inefficient use of resources. Intelligent monitoring can dynamically optimize operational parameters. For example, after renovation, a plant in Qinhuangdao achieved a 12% reduction in electricity usage, saving over 80,000 yuan annually and recouping the investment in less than a year. The TuasNexus facility in Singapore reduced its electricity consumption per ton of water by over 30%, cutting its carbon emissions by more than 200,000 tons annually, with carbon trading revenues covering part of the operational costs. Global evidence shows that intelligent monitoring can reduce the overall energy consumption of wastewater plants by 15%-40%. Medium-sized plants (30,000-100,000 tons/day) benefit most from energy savings, typically saving over 500,000 USD annually in electricity costs. After a renovation, a 50,000 tons/day plant in China reduced aeration energy consumption from 0.55kWh/m³ to 0.42kWh/m³, saving 1.2 million kWh annually.

Traditional equipment maintenance relies on regular inspections, which can easily overlook potential faults. Unexpected downtime not only disrupts processes but also leads to high repair costs. Intelligent monitoring, however, can track equipment data such as vibration and temperature in real-time, allowing for early detection of potential failures. Under traditional methods, the average failure rate of core equipment is 7%-10%, but after intelligent upgrades, it can be reduced to below 3%, with unplanned downtime decreasing by more than 70%. Suez Group uses digital twin technology to extend membrane cleaning cycles by 20%-30%, reducing operations and maintenance staff by 30%-45%. After the renovation of China's Honghu Smart Water Plant, equipment maintenance work orders dropped by 18%, unplanned downtime was reduced by 50%, and the average lifespan of the equipment increased by 15%-20%.

In fact, smart monitoring is not a “high investment, difficult implementation” scenario. There are adaptation plans for wastewater plants of different sizes, with an investment return ratio far exceeding expectations. The Hyperion Water Reclamation Plant in Los Angeles, USA (1.74 million tons/day) will begin its intelligent upgrade in 2024. The current effluent compliance rate is stable at over 98%, and the plant is progressing toward net-zero emissions. After renovation, similar large-scale plants globally can optimize operations and maintenance staff by more than 30%, saving over $2 million annually in electricity costs. For medium-sized plants, a renovation investment of $3-5 million can save $500,000 to $1 million annually, with a payback period of 3-4 years. After a renovation in a 50,000 tons/day plant in China, the cost per ton of water decreased by over 20%, saving 1.626 million yuan annually; another plant of the same size invested 50 million yuan, saving 7 million yuan annually, with a payback period of just 3.2 years. Small plants can implement step-by-step upgrades, and in Southeast Asia, several small plants have an initial investment of $80,000 to $120,000, saving $30,000 to $50,000 in electricity costs annually, with a payback period of 2-3 years. This model has been widely promoted in developing countries.

Intelligent upgrades don’t require a “one-size-fits-all” approach; customizing solutions and implementing them step-by-step is the most reliable method: In 3-6 months, basic monitoring can be improved, reducing manual labor by 70%; in 4-8 months, core control can be optimized, achieving a 15% reduction in energy consumption and a 20% reduction in chemical consumption; further steps will establish a full-process smart platform for predictive maintenance. It’s important to note that the effectiveness of these upgrades depends on technology choices and management levels, and should be adapted to each plant’s specific needs. Globally, the focus in wastewater plant competition has shifted from “treatment capacity” to “operational efficiency.” Smart monitoring is not a “flashy technology” from Europe and the U.S., but a practical solution for stable effluent, low energy consumption, and cost savings. It is also key to achieving SDG 6, a goal that still has a long way to go globally and requires joint efforts from the industry. For most wastewater plants, implementing intelligent monitoring now is not only in response to environmental policies but also a way to reduce burdens and save money. What are the pain points for wastewater plant operations in your area? Have you started any intelligent upgrades? Feel free to share in the comments.

hthrjt2017@gmail.com

hthrjt2017@gmail.com