- release date: 2022-08-30 12:00:34

- author: Hongtai Huairui

- Reading: 3850

key words: Fiber felt activated carbon adsorption and desorption, catalytic combustion, coating exhaust gas, coating VOCs pollution

Hongtai Huarui Technology Group welcomes your visit. We have been dedicated to the environmental protection and governance industry for over a decade! We look forward to a cooperation with you!

key words: Fiber felt activated carbon adsorption and desorption, catalytic combustion, coating exhaust gas, coating VOCs pollution

project overview

A certain automobile trim coating process in Wuhan uses a large amount of organic solvents for oily paint during the production process. The pollutants are mainly organic pollutants produced by the evaporation of paint and solvents. The main components are ethyl acetate and benzenes (toluene, xylene, etc.). Honeycomb activated carbon adsorption equipment was originally used for purification treatment. Due to the low treatment efficiency (about 60%) and the need to regularly replace honeycomb activated carbon after adsorption saturation, hazardous waste generated also needs to be treated; this time, the environmental protection equipment will be upgraded and replaced with a new purification equipment.

Design basis

At present, the common VOCs waste gas treatment methods include: combustion method, adsorption method, condensation method, chemical oxidation method, low-temperature plasma method, photocatalytic oxidation method and biodegradation method. In the "Feasible Technical Guidelines for Pollution Prevention and Control in the Coating Industry" issued by the Ministry of Ecology and Environment, it is recommended to use adsorption method, combustion method, condensation method or a combination of processes thereof for treatment. In the actual application process, according to the actual pollution production of the enterprise, the enterprise can reasonably choose the process for the project matching.

Design principles

The coating exhaust gas first enters the scrubber washing and dry filtration equipment, and then passes through the fiber felt activated carbon adsorption box 1, 2, 3 adsorption treatment, and the treated exhaust gas is discharged through the adsorption fan and exhaust cylinder. At this time, the catalytic combustion furnace is preheated, and when the catalytic ignition temperature of ethyl acetate reaches 260°C, the corresponding valve and desorption fan are opened. The air is heated to about 100 °C by the heat exchanger to desorption the activated carbon adsorption box 4, and the desorbed exhaust gas enters the electric heater of the catalytic combustion furnace to heat to the ignition temperature of 260 °C, and the catalytic combustion reaction forms carbon dioxide (CO2) and water vapor (H2O). The burned exhaust gas is recovered by a heat exchanger and discharged to the exhaust cylinder (chimney) by a desorption fan.

Source of pollution

According to the original equipment of the enterprise and the feedback of the collected effect, the exhaust volume of the printing production line is about 40,000m³/h, and according to the statistics of the original exhaust pipeline detection data, the concentration of VOCs imported from the exhaust gas treatment equipment is about 100~300mg/m³.

Processing technology

The working process of this device can be divided into 4 process sections, scrubber, dry filtration stage, fiber felt activated carbon adsorption stage, and fiber felt activated carbon desorption and regeneration stage.

2-1 Scrubber

When the organic waste gas passes through the scrubber, the particulate matter (paint mist) in the exhaust gas can be effectively intercepted by the water mist and environmental protection balls in the scrubber, and the gas components and particulate matter components are separated and entered into the lower processor for treatment.

2-2 Dry filtration stage

After the exhaust gas discharged from the workshop enters the scrubber device, the organic waste gas also contains water mist and a trace amount of paint mist at this time, and the water vapor is removed by the water baffle and mist eliminator in the dry filtration device, and then the primary effect and bag filter are used to intercept a trace amount of paint mist, and the gas components and particulate matter components are separated again and entered into the lower processor for treatment.

2-3 Fiber felt activated carbon adsorption stage

When the organic waste gas passes through the activated carbon layer, the organic components in the exhaust gas are attracted to the micropores of the activated carbon and concentrated in it, and the organic components are separated from its components, and the other components (clean gas) are discharged by the fan.

2-4 Activated carbon regeneration stage of fiber felt

After a certain amount of solvent is adsorbed, the adsorption capacity will be reduced or lost due to the gradual increase of the adsorption capacity. When regenerating, the combustion chamber is heated up by preheating, and when the temperature reaches the ignition temperature, it switches to the desorption route to desorption and regeneration the activated carbon adsorption tank.

The specific process flow diagram is shown in Figure 1.

Handling indicators

The exhaust gas emission standards of the project implement the emission standards of DB33/2146-2018 "Air Pollutant Emission Standards for Industrial Coating Processes". The emission requirements are as follows: non-methane total hydrocarbons (ethyl acetate, etc.) ≦ 40mg/m³, and the emission rate ≦ 1.5kg/h.

Run the result

1. Pollutant monitoring data

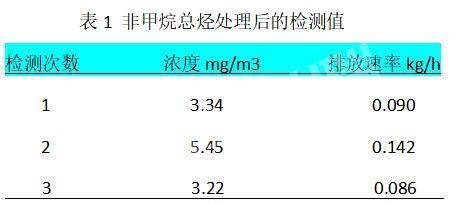

After the normal operation of the project, the equipment was monitored for several weeks during different operating periods, and a local third-party certification company was entrusted to use standardized detectors to test the concentration indicators of import and export VOCs. The main detection values are shown in Table 1.

The removal rate of non-methane total hydrocarbons reached more than 90%.

2. Investment and operating expenses

The project investment is mainly in the equipment and installation of fiber felt activated carbon adsorption equipment, filters, fans, catalytic combustion beds, ventilation pipelines, desorption combustion pipelines, automatic control systems, etc., with a total investment of about 1.9 million yuan. The operating cost of the system is mainly due to the power consumption of the equipment, and the waste gas is 40,000 m³/h, 24 hours a day. The electricity consumption is about 120KW*h, and the electricity price is 1.0 yuan/(KW*h), that is, the electricity cost for treating 1m³ of exhaust gas is 0.003 yuan

epilogue

After the upgrading and transformation of the exhaust gas treatment facility, the overall removal rate is more than 90%, and after it was put into use in 2018, the exhaust gas pollution emissions of the automobile trim coating have been greatly reduced, and the environmental odor of the factory area has been significantly improved, and there are no odor complaints.

Previous Article:Design of wastewater treatment station f...

Next Article:Smart and environmentally friendly toile...

Environmental Protection Information

Recommended Products