Friends who do sewage treatment have a high probability of having this dilemma: In the sludge dewatering process, should we choose a stacking screw press or a plate and frame filter press? Both models are mainstream equipment in the industry, but when used in practice, issues such as efficiency, cost, and land occupation always make people uncertain.

In fact, there is no need to rush to conclusions. We may wish to start from the core confusion in actual use and slowly sort it out based on measured data. After all, equipment selection is not absolutely optimal. It can only be adapted or not and suit our own processing scenarios, budgets and needs. It is the safest choice.

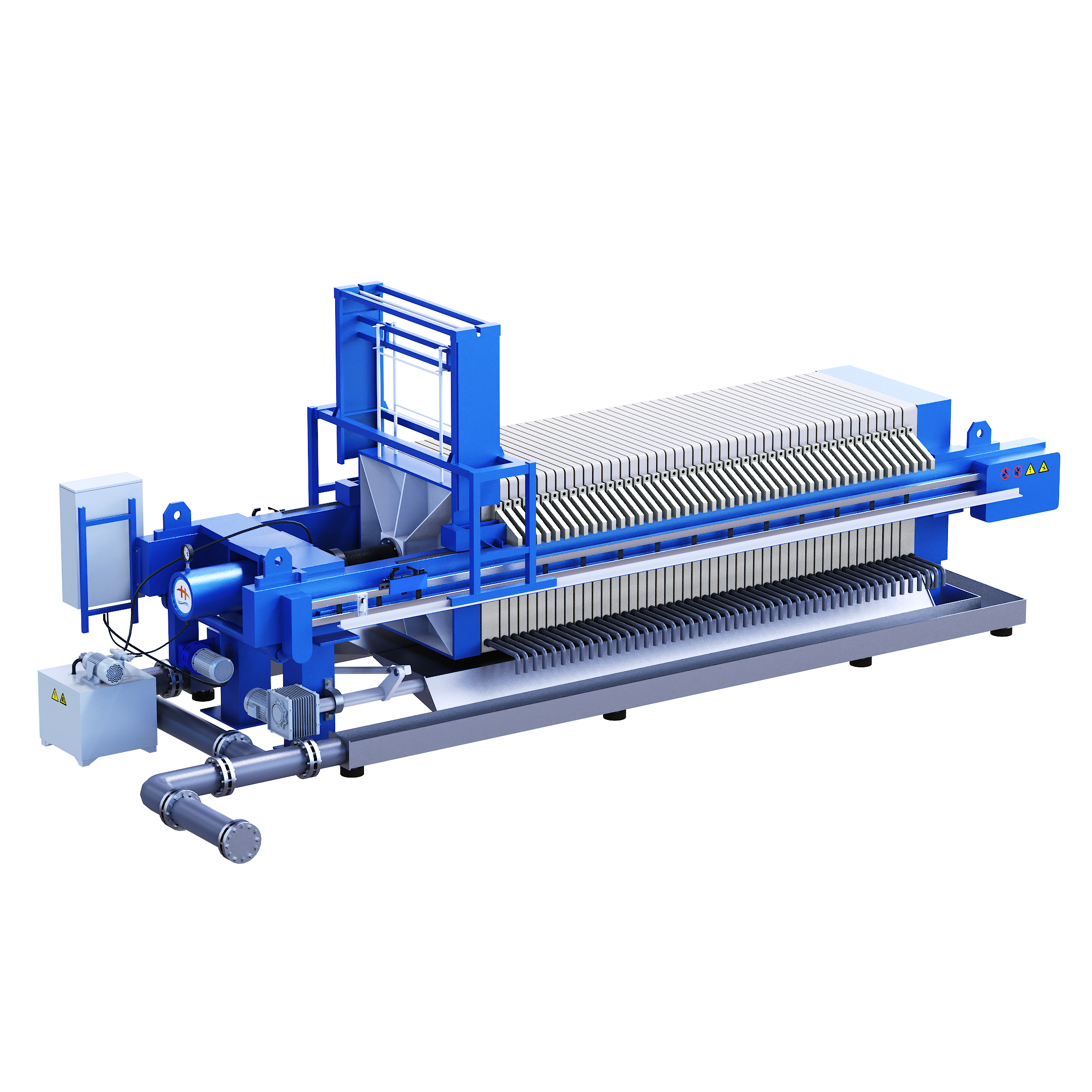

Let's first say that everyone is most concerned about treatment efficiency, which is directly related to whether the sludge disposal task can be completed on time. Many people will first look at the rated processing capacity of a single machine and feel that the plate and frame filter press has more advantages. Large models can reach 30-100 tons/hour (wet sludge) under ideal working conditions, and the filtration area is 500 square meters. In theory, it can process 100 tons per hour.

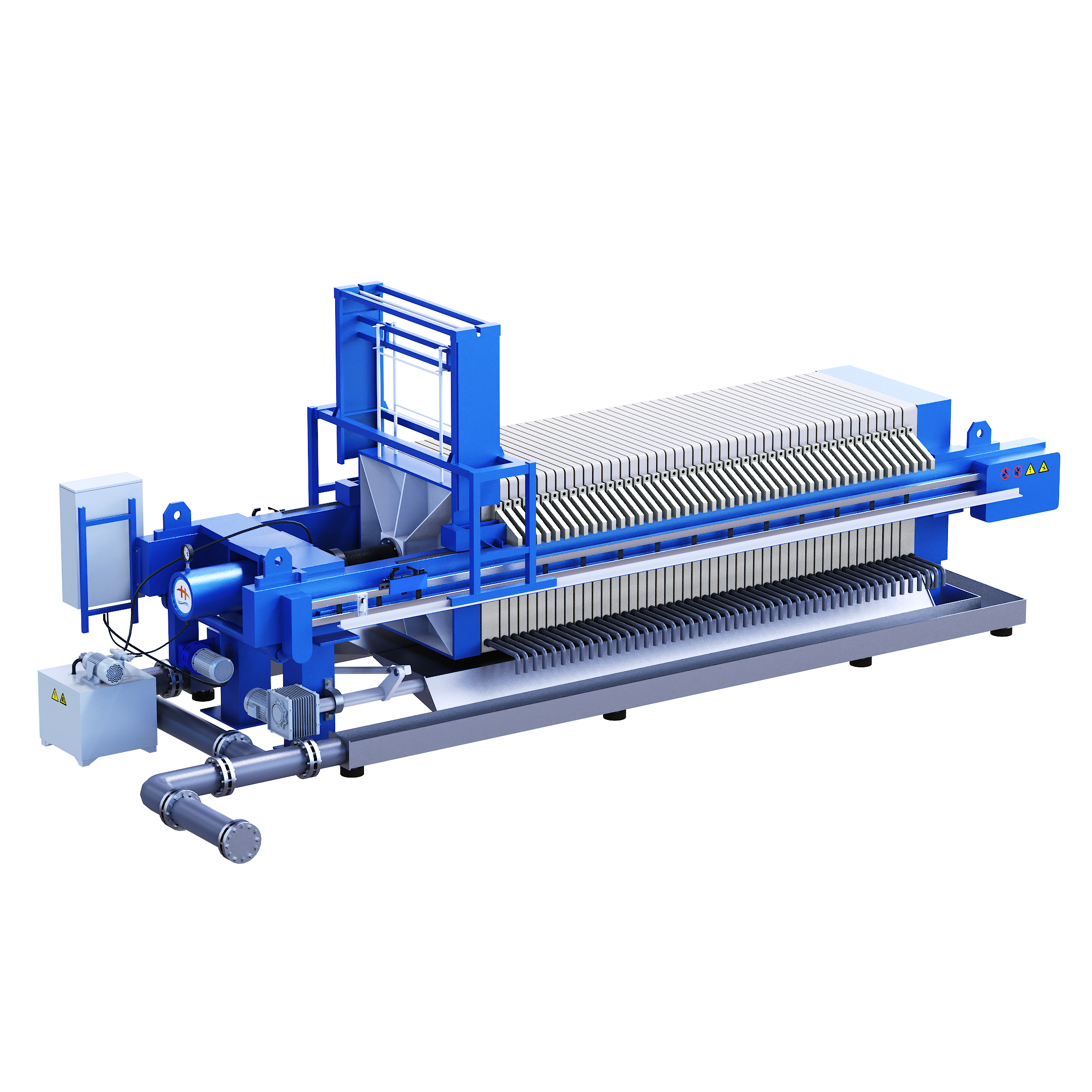

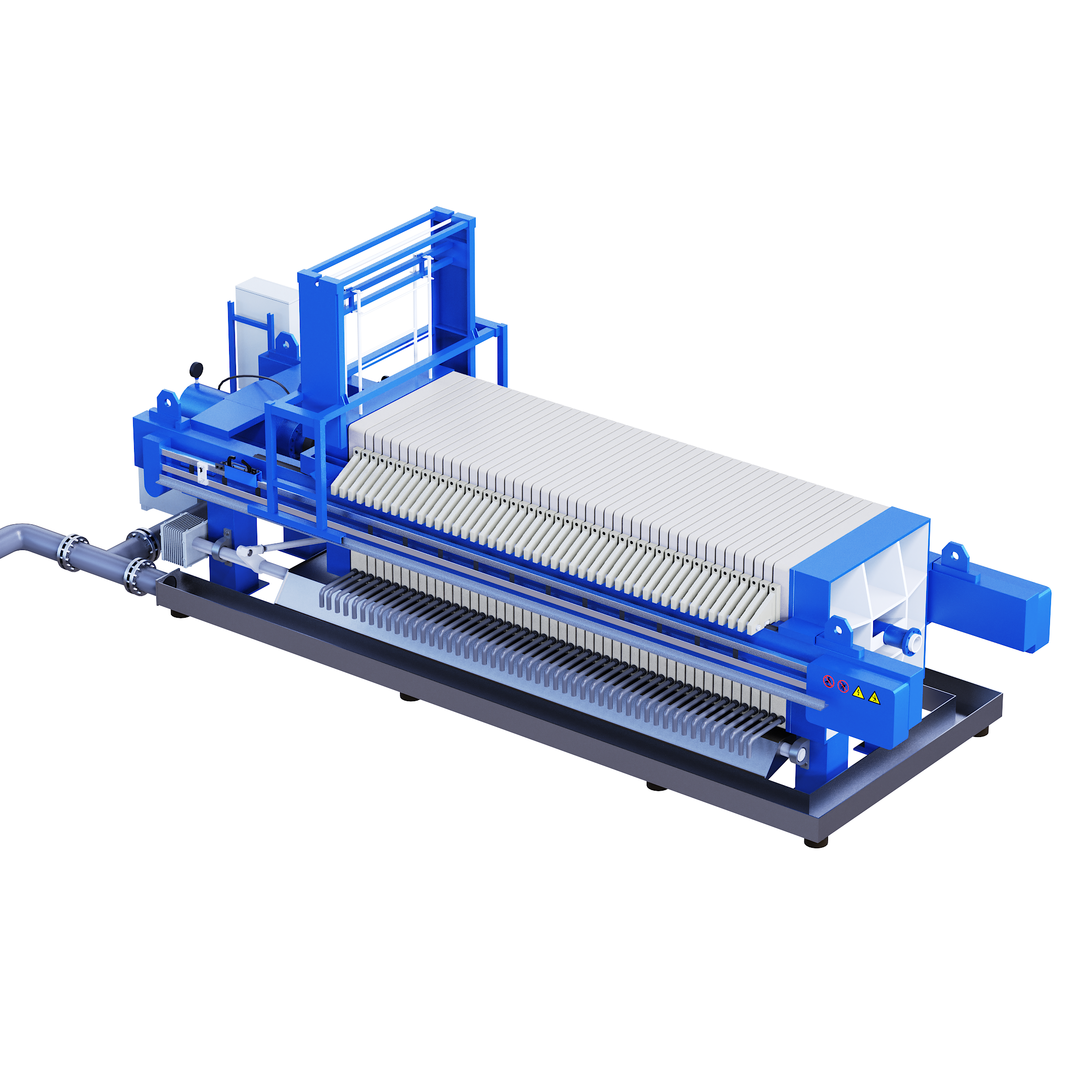

However, in actual use, we discovered that the plate and frame filter press has an unavoidable problem: it operates intermittently. Each batch of sludge is processed, it has to go through a set of processes of compaction, feeding, washing, and cake unloading. The entire cycle usually takes 2-3 hours, and the effective operation time is only 12-16 hours per day. The actual average daily processing capacity can only reach 20-80m³, which is about 50%-70% of the continuous operation of equipment of the same specification.

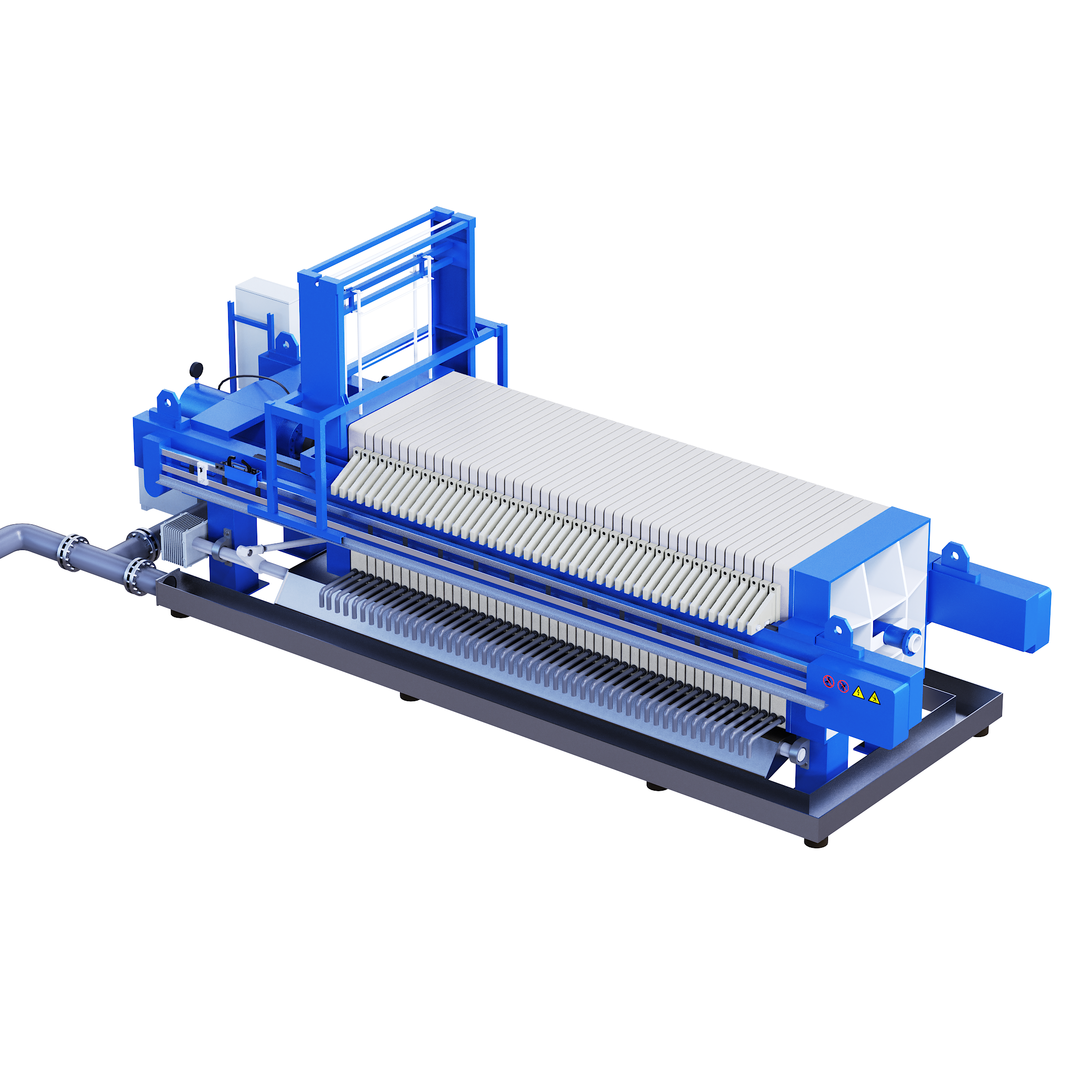

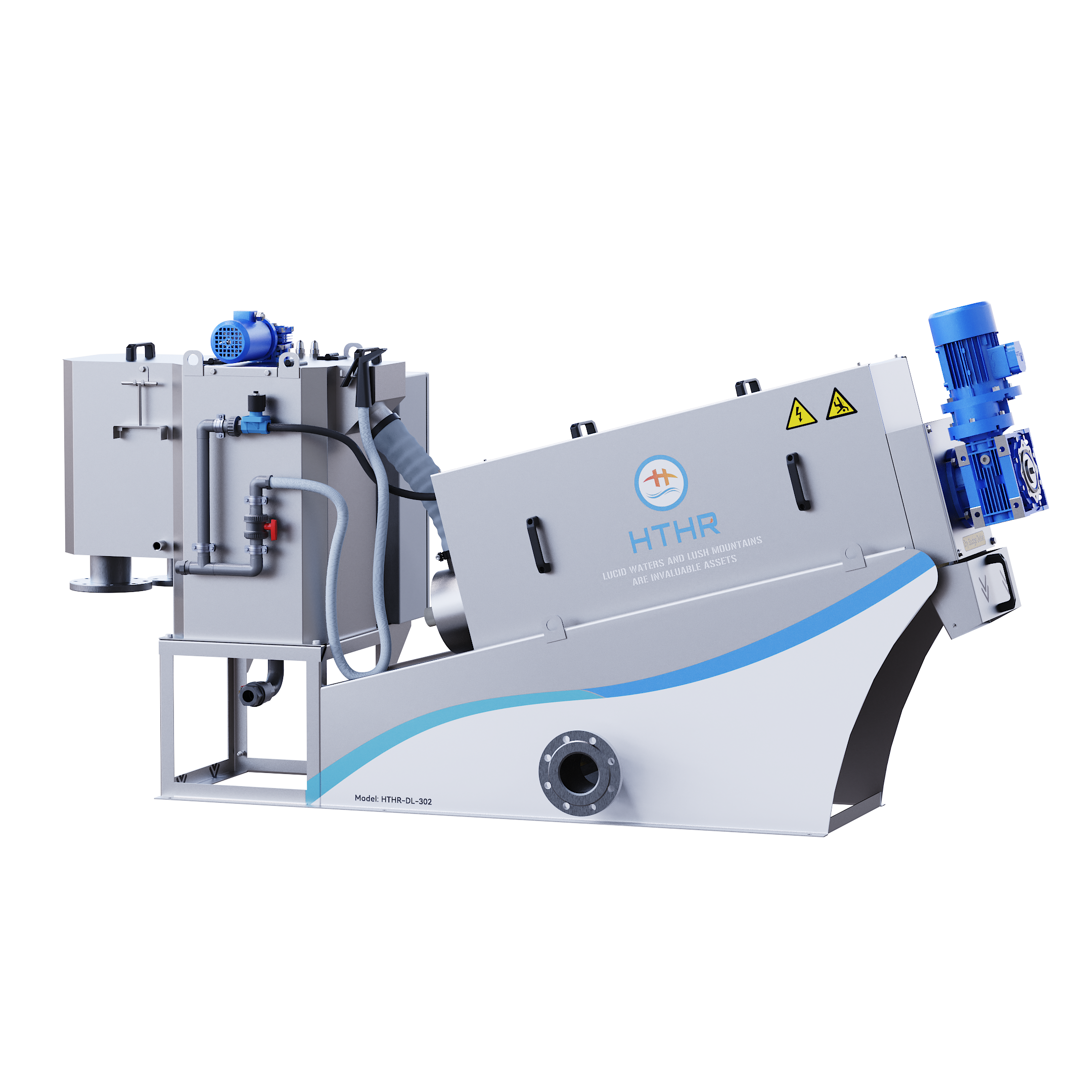

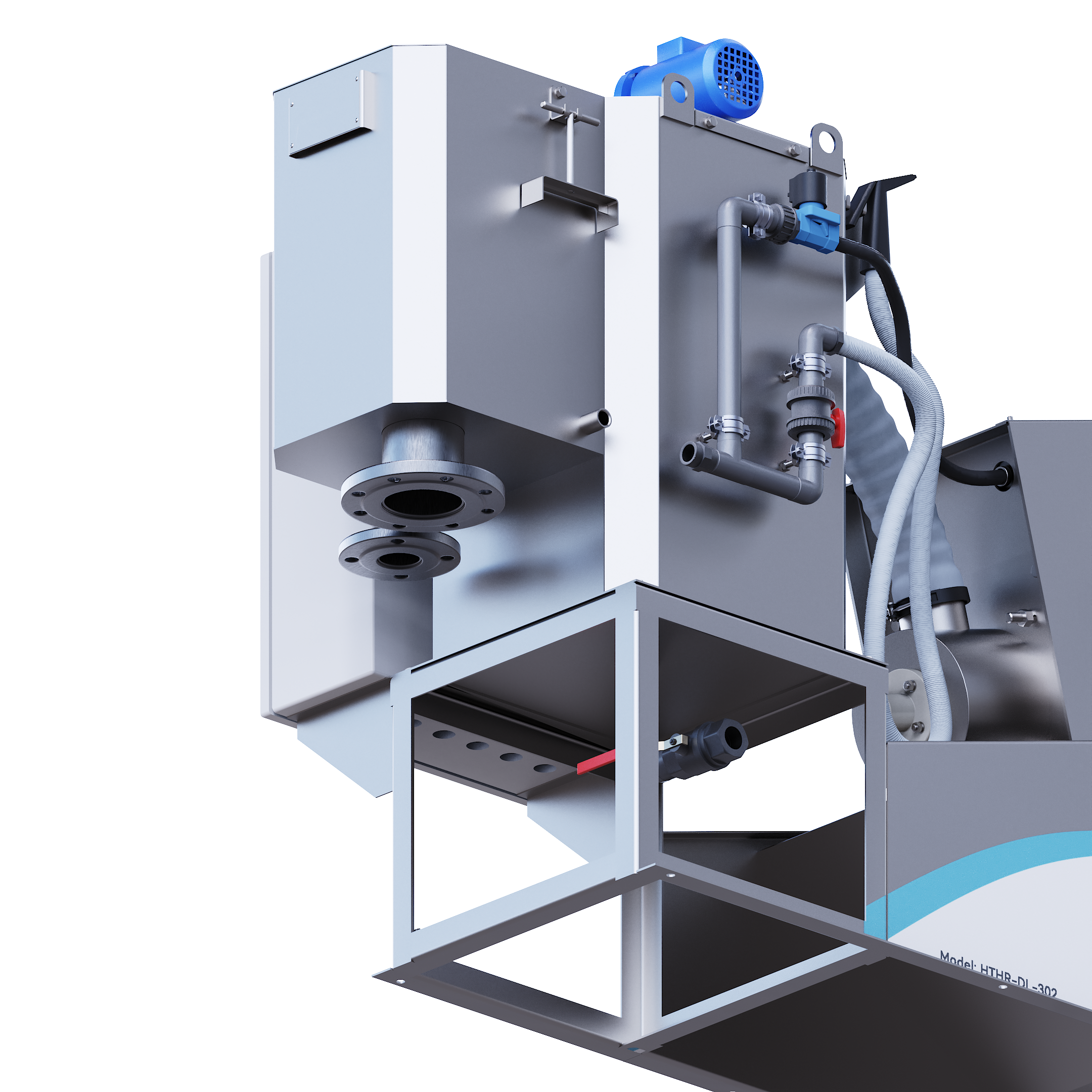

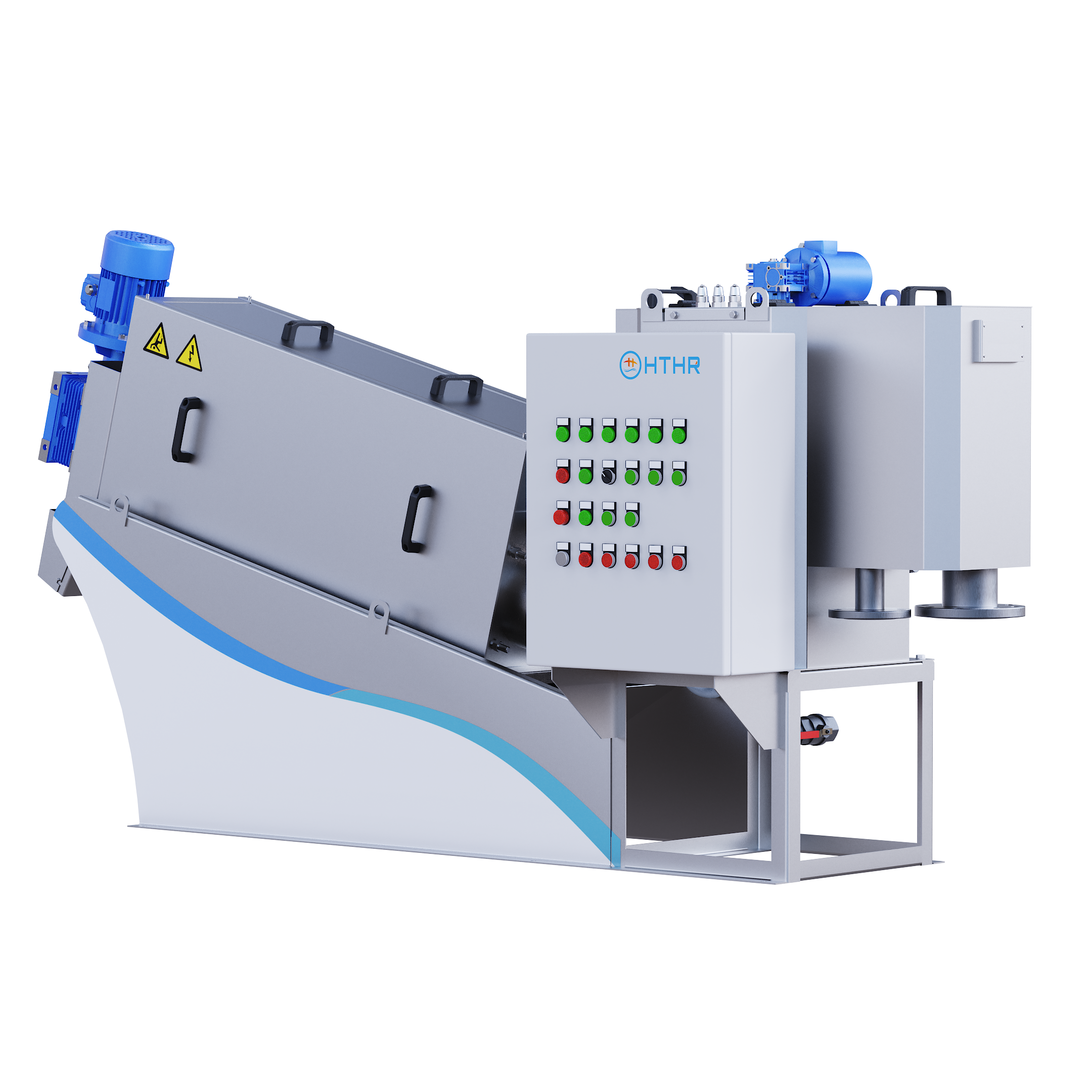

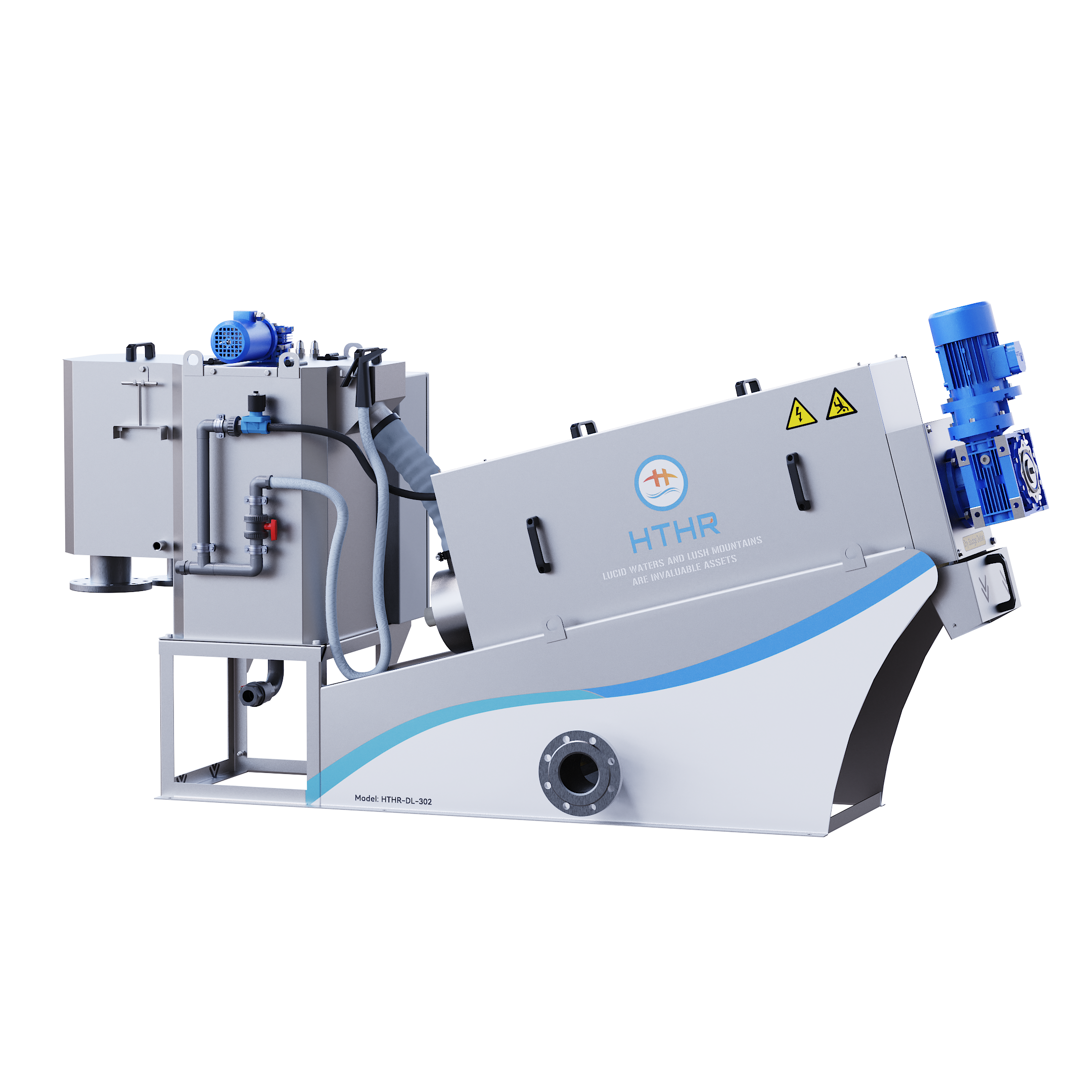

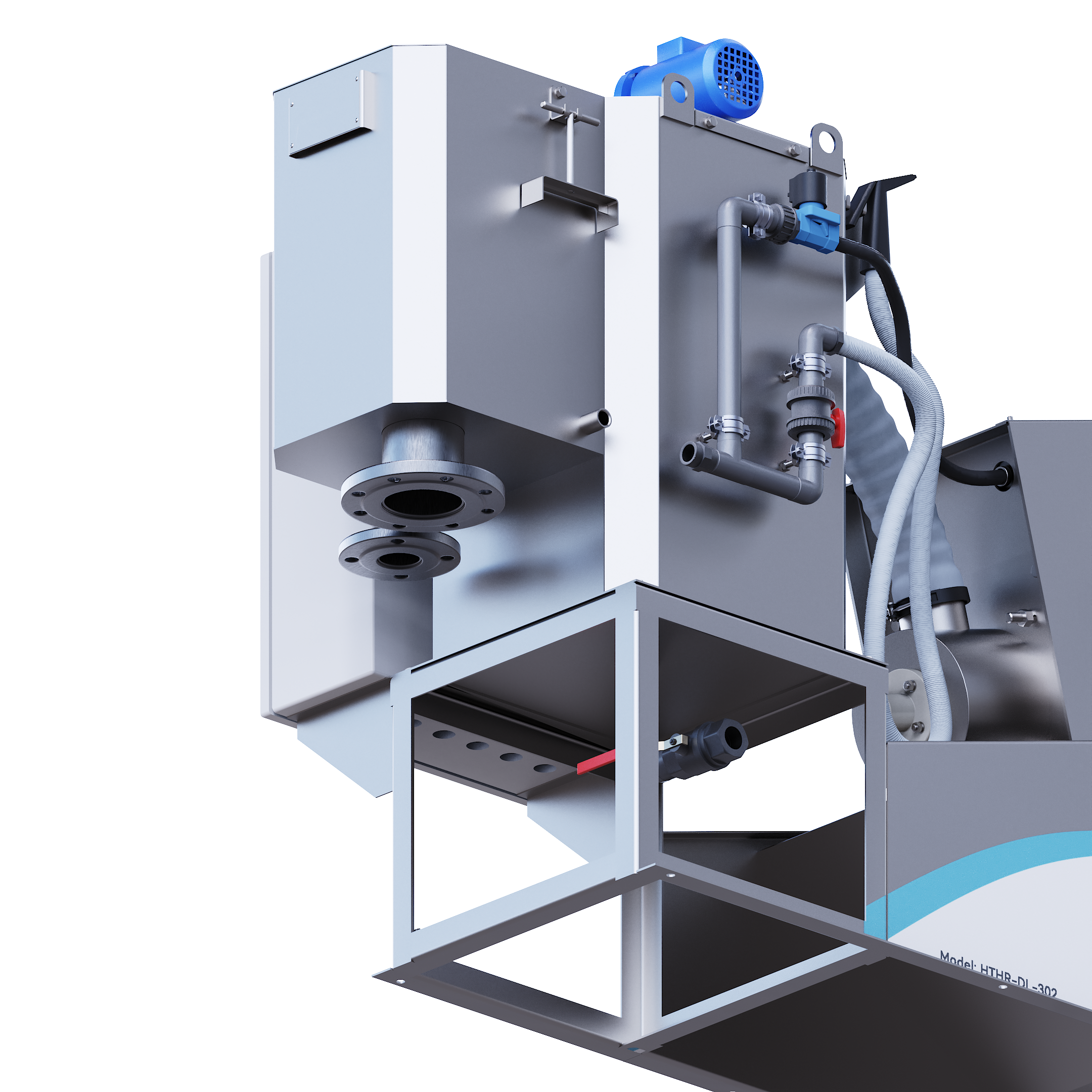

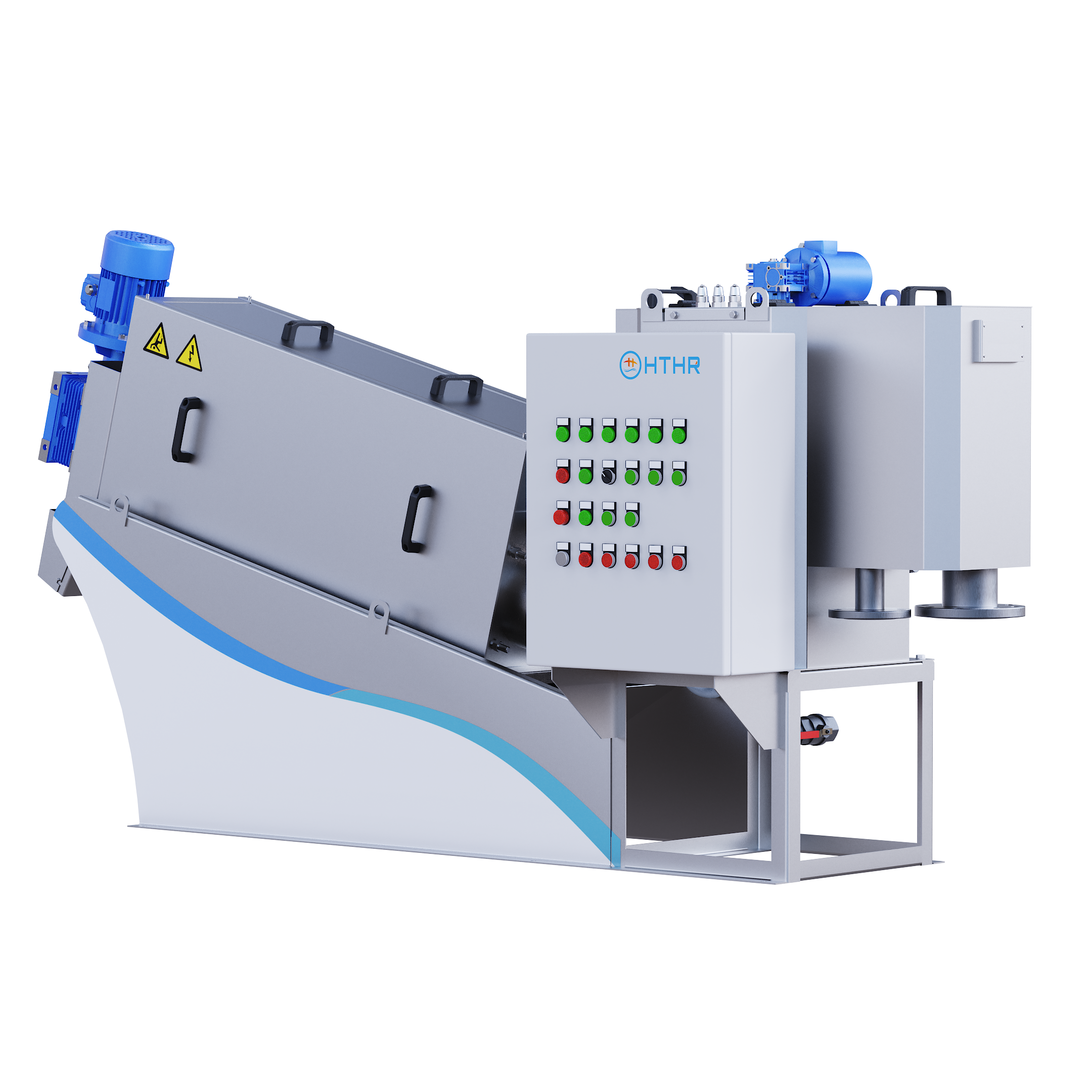

The stacking machine is different. It adopts a continuous treatment mode. After the sludge enters, the free water is first removed by gravity, and then it is slowly extruded and dehydrated through a helical shaft with a gradually changing pitch. There is no need to stop the whole process, and it is no problem to rotate continuously for 24 hours. The processing capacity of a single screw stacker is 0.5-20m³/h (wet sludge). Based on absolute dry sludge, small equipment can process 8-20kg per hour, and large equipment can reach up to 720-1200kg.

Although the rating of a single unit is not as good as that of a large plate and frame filter press, it is advantageous in its stability and continuity, and the average daily processing capacity will not be discounted. Moreover, it can be expanded through modular combinations. For example, small and medium-sized sewage treatment plants, the average daily sludge volume is below 50 tons, using a stacker is more efficient. If it is a large-scale scenario with an average day of more than 500 tons, the plate and frame filter press has the advantage of single scale, and multiple units can be connected in parallel to make up for the shortcomings of intermittent operation.

In addition to treatment efficiency, the dehydration effect is also critical. The drier the mud cake, the lower the cost of subsequent transportation and disposal. Judging from actual operating data, the difference in dehydration capacity of the two equipment is obvious.

Under standard working conditions, the moisture content of the dehydrated mud cake is about 75%-85%, which can fully meet the environmental protection requirements of conventional disposal such as landfill and incineration pretreatment. If the flocculation process is optimized and the extrusion structure is upgraded, the water content can be reduced to 60%-68%, and it can even be stabilized at 60%-75% when treating river silt.

Plate and frame filter presses have inherent advantages in dewatering effect. The moisture content can be controlled at 60%-70% under standard working conditions, and can be stably dropped below 60% after optimizing the process. Especially for processing industrial sludge with high inorganic content, the moisture content can be as low as 50%-55%, and in some scenarios it can even reach an ultra-dry state of 15%.

Take domestic sludge treatment as an example, the moisture content after treatment by a stacker is 75%-80%, and the plate and frame filter press can achieve 40%-60%. The volume of the latter mud cake is only equivalent to 1/3 of the former. -1/2, subsequent transportation and disposal costs can be directly reduced by more than 30%. Therefore, if high requirements are required for clay biscuit content, such as sludge incineration or resource utilization, a plate and frame filter press is obviously more suitable.

After discussing the treatment effect, we have to calculate the economic account, energy consumption and maintenance costs, which are expenses that cannot be avoided in long-term operation. Looking at energy consumption first, the advantages of the stacker are outstanding. It is driven by a low-speed screw shaft, the speed is only 2-4 revolutions/minute, and the unit power consumption is only 0.01-0.1kWh/kg-DS (absolute dry sludge), which is almost 1/8 of the belt filter press and 1/20 of the centrifuge.

Based on the average daily processing of 100 tons of sludge and the electricity bill of 0.8 yuan/kWh, the stacker operates continuously 24 hours a day, and the electricity bill per year is about 105,000 yuan. Because plate and frame filter presses need to push sludge at high pressure, the pressure needs to reach 0.6-2.0MPa, and the energy consumption is much higher. The unit power consumption of traditional models can reach 14kWh/t. Even high-efficiency intelligent models still need 1.3- 1.6 kWh/ton of dry mud.

Similarly, it processes 100 tons of sludge per day, and the plate and frame filter press runs for 8 hours per day. The annual electricity bill is about 146,000 yuan, which is 39% higher than that of the stacker press. Fortunately, hydraulic technology and intelligent control are now being upgraded. The energy consumption of some new plate and frame filter presses has dropped by 29.8% compared with the industry average in 2021, and the energy saving potential is still being released.

The maintenance cost gap is even more obvious. There are few wearing parts for the screw stacking machine, mainly dynamic and static rings and spiral shaft bearings. The dynamic and static rings can be used for 1-5 years, and the bearings are replaced once a year. The annual maintenance cost of a single equipment is about 4000 yuan. Moreover, it is modular and easy to assemble and disassemble. The cleaning cycle can be up to 15 days. It can basically achieve zero blockages and zero downtime throughout the year. Usually, only one person needs daily inspection.

The core vulnerable parts of the plate and frame filter press are filter cloth, which has to be replaced every 3-7 days. Coupled with the replacement of hydraulic seals once a year, the annual maintenance cost of a single equipment is about 137,000 yuan, which is 34 times that of a stacker machine. What is even more troublesome is that the filter cloth must be stopped. Traditional plate and frame filter presses must be stopped about three times a month, which not only delays the processing progress, but also increases the shutdown losses.

In addition to efficiency and cost, site conditions are also hard constraints for many users, especially sewage treatment plants or old facility renovation projects in cities, where there is often not much extra space. At this time, the compactness of the screw stacker is reflected. It integrates the flocculation reaction tank and the cleaning device. The smallest model covers an area of only 0.86 square meters, the medium-sized equipment covers an area of less than 7 square meters, and the large-sized equipment only covers an area of 10 square meters. About meters, the overall area is only 1/3-1/5 of traditional equipment.

Plate and frame filter presses cover a much larger area. Small equipment is okay, with a filtering area of 1 square meter covering an area of about 0.64 square meters. However, large equipment such as a filtering area of 250 square meters can cover an area of 15-30 square meters. Moreover, it also needs to reserve additional space for filter plate storage, temporary storage of sludge, and cleaning. The actual total area is usually 1.5-2 times that of the equipment body. Under the same processing capacity, it occupies a lot more space than the screw stacker.

The degree of automation is directly related to labor costs and operational stability. Nowadays, mainstream screw stacking machines are basically highly intelligent. They are equipped with PLC control systems, frequency conversion speed regulation and Internet of Things modules. They can monitor key parameters such as sludge concentration and equipment torque in real time, automatically adjust the speed and extrusion pressure, and are unattended 24 hours a day. There is no problem at all. If a fault occurs, it can also automatically alarm and support remote monitoring. Workers only need to inspect it once a day.

The automation level of plate and frame filter presses has also been improved in recent years. High-end models have been able to realize unmanned operation of the entire process of automatic pressing, unloading, and cleaning of filter plates. It is expected that the industry automation rate will reach 78% in 2026. However, traditional models still require manual loading and unloading of filter plates and replacement of filter cloth. Even automated models require manual monitoring of cycle status because they are operating intermittently, and the overall reliance on manual is higher than that of stacker machines.

In fact, after sorting out, the adaptation scenarios of the two devices are already very clear. If your average daily sludge volume is less than 100 tons, the site is small, the labor cost is high, or the old facilities are renovated, which requires rapid production and long-term stable operation, and the requirements for the moisture content of the mud cake are not particularly stringent (60%-85%).), and the budget is also limited, the screw stacker is undoubtedly a more suitable choice.

On the contrary, if deep dehydration is needed, the moisture content of the mud cake must be controlled below 60%, such as sludge incineration or resource utilization, or large-scale projects with an average daily processing capacity of more than 500 tons, or processing industrial sludge, construction mud, a special sludge with a high inorganic content, will have more obvious advantages. If you already have a mature plate and frame filter press operating system and do not want to invest extra technology conversion costs, it is safe to continue to choose it.

As environmental protection requirements become higher and higher, sludge dewatering equipment is also developing in the direction of high efficiency, intelligence and green. Stacking screw presses are being upgraded to large-scale scale, improving stand-alone processing capabilities by optimizing the structure, and incorporating artificial intelligence technology to achieve predictive maintenance; plate and frame filter presses are focusing on solving the automation problems of filter plate loading and unloading and filter cloth replacement, and at the same time reducing energy consumption through energy-saving technology.

In the future, the technical boundaries of these two types of equipment may be further integrated. For example, high-pressure extrusion technology is introduced to improve the dewatering effect in the stacker, and the optimized operation mode of the plate and frame filter press will shorten the cycle period. For our users, the core selection no longer needs to worry about which indicator is the best, but needs to calculate the full life cycle cost, comprehensively consider initial investment, operating energy consumption, maintenance costs and disposal benefits, and find the equipment that best suits your needs.

In the final analysis, there is no absolute difference between stacking screw presses and plate and frame filter presses. The key lies in adaptation. I hope that these sorting based on measured data can help everyone avoid misunderstandings in selection, make the sludge dewatering process efficient and economical, and avoid detours and pits.

hthrjt2017@gmail.com

hthrjt2017@gmail.com