- release date: 2022-08-21 02:35:00

- author: Hongtai Huairui

- Reading: 4748

key words: Shanxi, food company,30m3, beef, processing, wastewater treatment, engineering

Hongtai Huarui Technology Group welcomes your visit. We have been dedicated to the environmental protection and governance industry for over a decade! We look forward to a cooperation with you!

key words: Shanxi, food company,30m3, beef, processing, wastewater treatment, engineering

project overview

The food company mainly deals in meat products such as beef jerky and canned beef. The raw material for meat processing is mainly frozen beef, so the wastewater discharged from the production workshop mainly comes from the thawing water of frozen beef, the washing water for washing utensils and the ground, and the cleaning wastewater generated during the processing process. The wastewater discharge is 30m3/d, and the wastewater contains high organic matter, oil and suspended matter, making it a high-concentration organic wastewater.

The wastewater treatment system adopts a combined treatment process of oil isolation precipitation + air flotation + two-stage biological contact oxidation. After treatment, the effluent meets the first-level emission standard of the "Discharge Standard for Water Pollutants in the Meat Processing Industry"(GB1457-92). The total installed capacity of the wastewater treatment system is 9.25kW, and the operating cost is about 1.2 yuan/m3 wastewater (excluding depreciation).

Design basis

(1) "Water Pollutant Discharge Standards for Meat Processing Industry" (GB13457-92);

(2) Various relevant basic information provided by the builder (water quality, water quantity, discharge requirements, etc.):

(3) On-site survey data;

(4) Relevant national, provincial and regional regulations, regulations and document spirit:

(5) Other relevant design codes and standards.

2. Design principles

(1) Conscientiously implement the national guidelines and policies on environmental protection, so that the design complies with relevant national regulations, norms and standards;

(2) Comprehensively considering the characteristics of wastewater quality and quantity, the treatment process should be technologically advanced, stable and reliable, economically reasonable, flexible and safe and applicable.

(3) Properly treat and dispose of sludge and scum generated during wastewater treatment to avoid secondary pollution;

(4) The automatic control system of the wastewater treatment system should be convenient to manage, safe, reliable, economical and practical;

(5) The layout of the wastewater treatment system should be compact, reduce land occupation and investment, and the elevation layout should adopt a three-dimensional layout as much as possible to make full use of the underground space.

(6) Properly consider the development prospects of the enterprise and leave room for design:

(7) Design in strict accordance with the defined conditions of the construction party to adapt to the actual situation of the project.

Design principles

The design scope of this project includes the process, civil engineering and structures starting from the water collection well to the outlet of the secondary sedimentation tank. equipment, electrical. Design of automatic control and water supply and drainage. It does not include the wastewater collection and discharge pipe network outside the wastewater treatment station, as well as the power supply, water supply, roads and greening inside the station from outside the station to the station.

The scope of services of this project includes:

(1) Design and construction of wastewater treatment system;

(2) Provision of wastewater treatment equipment and accessories in the equipment:

(3) All installation work in the wastewater treatment device, including electrical wiring in the equipment;

(4) Commissioning of wastewater treatment system until the commissioning is successful and runs smoothly:

(5) Free training of operators, coordination of operating procedures, and relevant operation records to provide strong technical support for future equipment maintenance and maintenance

Source of pollution

Mainly from the thawing water of frozen beef, the rinsing water of the rinsing utensils and the floor, and the cleaning wastewater generated during the processing process

Processing technology

Because the raw materials used in the processing plant are mainly frozen beef, the wastewater discharged from the production workshop mainly comes from the thawing water of frozen beef, the rinsing water of washing utensils and the ground, and the cleaning wastewater generated during processing. This type of wastewater has the characteristics of large range of water quality and water quantity, high concentration of organic pollutants, and high concentration of suspended solids.

According to the specific situation of the wastewater, the following basic evaluation is made,

(1) The raw water is organic wastewater with low and medium concentrations, BOD/COD=0.47, good biodegradability, and easy to be treated by biological methods

(2) The oil content of raw water reaches 300mg/L, and the oil content is too high to enter the biological treatment system directly, so it needs to be pretreated first to reduce the oil content in the wastewater to the appropriate biological treatment standard.

(3) Due to the large change in the discharge of wastewater, it generally changes with the changes of off-peak processing seasons, holidays, etc., so it is necessary to do a good job in adjusting water quality and quantity to ensure the continuous and normal operation of subsequent treatment structures.

(4) Wastewater treatment requirements are high. The COD value of wastewater is 1500mg/L, the effluent is required to be less than 80mg/L, and the removal rate is 94.7%.

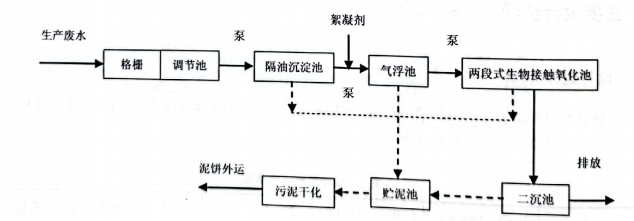

Process

At present, biological methods are mostly used at home and abroad to treat this type of wastewater, and the wastewater treatment volume for this project is small (30m).3/d). Consider using the one-by-one biofilm method suitable for small-scale water volume. Combined with the water quality characteristics of the meat processing wastewater, the two-stage biological contact oxidation process with mature technology is used as the main process of wastewater treatment. The specific process flow is detailed in Figure 2.

Fig. 2 Beef processing wastewater treatment process

Process description

This process is divided into two major systems, one is the pretreatment system, but the second is the biochemical treatment system, including the two-stage biological contact oxidation tank and the secondary sedimentation tank, the specific process description is as follows.

After the grid removes the large suspended solids and other impurities in the wastewater, it flows into the conditioning tank, where the water quality and quantity of the wastewater are adjusted to reduce the impact of water quality and water quantity changes on the subsequent treatment structures.

The water from the regulating tank is lifted into the oil sedimentation tank through aggregation, and the oil sediment plate is set up in the pool to isolate a large number of oil slick teams in the water, and capture most of the oil slick in the wastewater through the special flocking filter belt on the auxiliary oil machine, and the oil slick made from the filter belt is separated again in the oil storage tank, the oil is in the recycling bin, and the water flows back into the pool

The effluent of the oil sedimentation tank is lifted into the air flotation tank by the pump, and the emulsified oil and large first part of the suspension in the wastewater are removed by adding chemicals and coagulation in front of the air flotation tank. The air flotation tank is to take advantage of the different solubility characteristics of water under different pressures, and the air sent by the air compressor to the air tank is brought into the dissolved gas tank through the jet device, and is forcibly dissolved in the water under pressure to form dissolved water and sent to the air float tank. In the case of sudden release, the air dissolved in the water precipitates to form a large number of microbubbles, and the suspended matter sent by the copolymerization and is condensing after dosing is fully contacted, and is adsorbed in the suspended matter to be collected in the process of slow rise, so that its density decreases and floats to the water surface, so as to achieve the purpose of removing pollutants such as emulsified oil, SS and COD.

The effluent of the tile floating tank is lifted into the two-stage biotechnology contact gasification tank by the pump, relying on the microbial ecosystem dominated by high-efficiency compound microbial flora composed of suspended phase activated sludge and attached phase biofilm, combined with ultra-fine bubble gas technology, to achieve the synergy of physics, chemistry and biology, so that the organic and even inorganic pollutants in the dissolved state, colloidal state and some insoluble states of wastewater are transformed into stable and harmless substances, so that the wastewater can be purified.

The white flow of effluent from the two-stage biological contact oxidation tank enters the secondary sedimentation tank, and the biofilm and some fine suspended solids shed in the biochemical treatment reaction section are separated from the solid-liquid, and the effluent can be discharged to meet the standards.

The sludge from the oil sedimentation tank, the sludge from the secondary sedimentation tank and the scum from the air flotation tank enter the sludge storage tank, and then enter the sludge drying tank for drying and dehydration.

Process characteristics

The biggest feature of this process is the use of two-stage biological contact oxidation treatment technology, which has the following characteristics.

(1) The volume load of the biological contact oxidation method is high, and compared with the equipment of the same volume size, it has the significant advantages of short treatment time, saving floor space and high treatment capacity.

(2) The sludge mass concentration of the general activated sludge method is 2~3g/L, and the microorganisms are in suspension in the tank, while most of the microorganisms in the contact oxidation tank are attached to the filler. The concentration of microorganisms in water and on the filler in a unit volume can reach 10~20mg/L, which greatly improves the treatment effect due to the high concentration of microorganisms.

(3) Compared with the activated sludge method, the volume load of the contact oxidation method is higher, but the yield of activated sludge is reduced. Therefore, there is no need for sludge backflow.

(4) The two-stage biological contact oxidation method is little affected by the change of water quality and quantity, and the effluent water quality is excellent and stable: under the impact of poison and pH, the biofilm is little affected and recovers quickly.

(5) Strains that are prone to swelling (such as filamentous fungi) in the activated sludge method, while sludge expansion problems do not occur in the contact oxidation method

Handling indicators

According to the information provided by the builder, the total amount of wastewater designed is 30m3/d, the average processing capacity is 3m based on 10 hours of operation per day3/h. The design wastewater influent water quality indicators are shown in Table 1.

Table 1 Design wastewater influent water quality

|

project |

BOD5/(mg/L) |

CODcr/(mg/L) |

SS /(mg/L) |

Animal and vegetable oils/(mg/L) |

PH |

|

Influent water quality |

800 |

1500 |

500 |

300 |

6.0~8.0 |

3.2 Design effluent quality

According to the requirements of the construction party, the treated wastewater effluent meets the first-level standard of livestock slaughtering and processing in the (internal processing industry water pollutant discharge standard) (GB13457-92), and the specific effluent water quality requirements are shown in Table 2.

Table 2 Design wastewater discharge techniques

|

project |

BOD5/(mg/L) |

CODcr/(mg/L) |

SS /(mg/L) |

NH3-N/(mg/L) |

Animal and vegetable oils/(mg/L) |

PH |

|

The quality of the effluent |

≤25 |

≤80 |

≤60 |

≤15 |

≤15 |

6.5~9.0 |

Process effect prediction

Table 3 Prediction table of treatment effect of each unit

|

index |

cop,, |

BOpy |

ss |

Animal and vegetable oils! |

|

|

Grille |

Encounter water |

1 500 |

700 |

50o |

300 |

|

Water |

1 350 |

630 |

400 |

270 |

|

|

removal rate |

I0% |

I0% |

20% |

10% |

|

|

Oil separation sinking ingot |

l 350 |

630 |

400 |

270 |

i350 |

|

1215 |

598.5 |

360 |

108 |

1215 |

|

|

10% |

5% |

10% |

60% |

10% |

|

Previous Article:Renovation project of wastewater treatme...

Next Article:Wastewater reuse and treatment project o...

The content you might be interested in

Environmental Protection Information

Recommended Products