Sewage treatment ozone oxidation technology

- release date: 2025-11-20 16:01:33

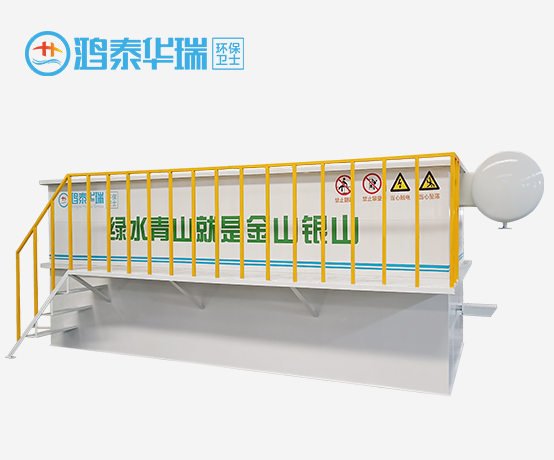

- author: Hongtai Huairui

- Reading: 719

- key words: Sewage treatment ozone oxidation

1. Introduction to ozone oxidation technology

Ozone has strong oxidation (oxidation potential 2.07V), engineering experience has found that although ozone can directly oxidize organic pollutants in wastewater, a single ozone oxidation technology has great limitations, in the process of treatment ozone dissolves in water to produce most of the reactive oxygen species and some hydroxyl radicals (OH), O3 dissolves in water to produce reactive oxygen species will preferentially react with pollutants with fast reaction rate, showing that O3 is selective for the removal of pollutants, so that pollutants with low reaction rate cannot be removed. The oxidation potential of hydroxyl radicals (OH) is 2.83V, which is the second strongest oxidant in nature after fluorine (3.06V), which can decompose organic matter into carbon dioxide and water.

Our company has developed two sets of ozone oxidation technology. One is to use jet aeration + atomization technology, and the other is to use ozone catalytic (SODO) oxidation technology.

2. Introduction to jet atomization oxidation technology

Jet atomization oxidation technology is to use jet mixed aeration equipment to dissolve more ozone in sewage, so that ozone molecules can contact more pollutant molecules and oxidize pollutants, because more ozone is dissolved in sewage, the production of reactive oxygen species and hydroxyl radicals (OH) will also increase accordingly, so that the organic matter oxidized by reactive oxygen species as intermediates will be oxidized by hydroxyl radicals (OH). In addition, atomization technology is used to directly contact the atomized sewage with the remaining ozone molecules that have not reacted, so that the pollutants that have not been completely oxidized are further oxidized.

Jet atomization ozone oxidation technology is divided into two processes, the first process of sewage atomizes the sewage through the atomization nozzle, the atomized sewage is in contact with the ozone in the reactor, and the organic matter in the sewage that is easily oxidized by ozone is selectively oxidized by ozone. The second process is to use the efficient oxygenation capacity of the venturi jet hybrid aeration equipment to dissolve more ozone in the sewage, so that more hydroxyl radicals (OH) will be produced, and pollutants that are not selectively oxidized by ozone molecules will be oxidized and decomposed by hydroxyl radicals (OH).

3. Introduction to the application of SODO plus catalytic oxidation technology

sODO plus catalytic oxidation technology is mainly used for standard discharge or upgrading transformation of sewage biochemical treatment, and can also be used for the treatment of RO concentrated water.

SODO catalyst is a heterogeneous ozone catalytic oxidation catalyst, which is composed of active components and supports, of which the active components are active transition metals/oxides (metal oxides of Mn, Fe, Co, Cu, Zn, Ni and Ce). The support is composed of activated alumina globules, activated carbon, ceramsites, porous zeolite, graphene, etc. The active components are similar in properties to the carrier material and have high adhesion strength. At the same time, through high-temperature sintering molding, the high utilization rate of active components is ensured, and the problem of catalyst loss rate is solved accordingly, and the reactor catalyst does not need to be supplemented, preventing secondary pollution.

The SODO plus process carries out catalytic oxidation treatment of wastewater, which can significantly increase the reaction rate of ozone and pollutants, and effectively reduce the treatment cost. With our ozone oxide tower equipment, the ozone dosage can be reduced by more than 30%, and the ozone utilization rate can reach more than 98%. Taking chemical wastewater pretreatment and printing and dyeing wastewater deep treatment as examples, the ozone amount required to be added can be reduced by 30% compared with conventional methods, and the operating cost per ton of water can also be reduced by 30%.

4. Operation and maintenance of SODO plus project

SODO plus adopts a proprietary process package, supporting proprietary automatic control software, and a variety of operation modes to monitor the operating conditions of the reactor in real time, saving labor costs for you.

hthrjt2017@gmail.com

hthrjt2017@gmail.com