1. Application research of MVR mechanical evaporation and recompression technology

Combined with the author's actual research, MVR mechanical evaporation and recompression technology is mainly used in the following specific industrial fields. The first is the field of seawater desalination. At present, reverse osmosis and distillation are the most commonly used practical methods for desalination technology in our country. Among them, there are three main types of distillation methods, including multi-stage flash distillation technology, low-temperature multi-effect distillation technology and pressure steam distillation technology. Combining the practical application of these technologies, the researchers roughly calculated the energy-saving effect of MVR technology in the field of seawater desalination, which was the most significant overall, reaching 8-12kWh/t. Researchers have made a lot of comparisons with TVR, MVR and other technologies, combined with evaporative condensers, compressors, water pumps, and preheater devices, and found that the losses are about 35%, 35.5, 17, and 11%, so when determining the compressor in the MVR device, it is necessary to choose a compressor with high performance and relatively low compression ratio.

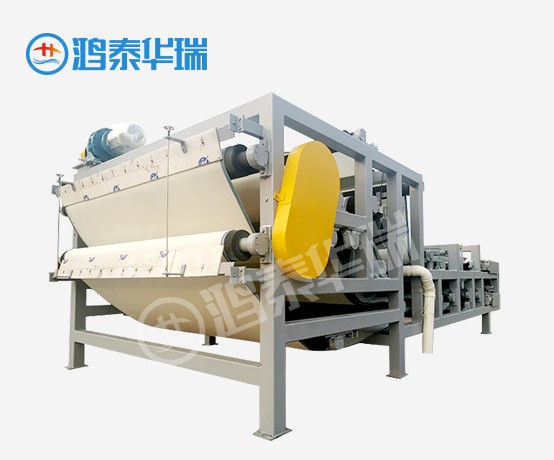

The second is in the field of wastewater treatment. For many high-salinity wastewater, the main components are generally ammonium nitrate, so combined with the purification of the physical and chemical filter box membrane, MVR technology for actual recycling treatment, and then technical treatment can generate concentrate and use it as chemical fertilizer for plants, including freshwater, which can also be used in various factories for drip irrigation and toilet flushing, so the overall social benefits are very significant. Wastewater treatment combined with MVR technology is chosen by many enterprises and is also the actual research object of this paper.

The third is the use in the field of salt production. In our country, many enterprises will choose the multi-effect evaporation technology in the evaporation technology to process salt, and in foreign countries, especially in developed countries, salt production is basically MVR technology; I believe that in the future, our country will gradually promote it. If MVR technology can be introduced into the field of salt production, it can well solve the problem of high overall cost, reduce the actual cost and expense rate, and improve the actual quality and quality of various edible salts is also very significant. Many scholars in our country have done a lot of research based on the actual situation on the southeast coast of our country, aiming to increase the evaporation concentration of ammonium sulfate and reduce the actual use of coal as a whole.

In addition to the above practical fields, MVR technology has also been widely promoted in the fields of emulsion products, paper industry, and distillation, so the overall actual development trend in the future is very good.

2. Research on the characteristics of MVR technology and other technologies in the recovery of high-salinity wastewater resources and the treatment of zero discharge problems

2.1 Advantages of MVR technology compared with other technologies

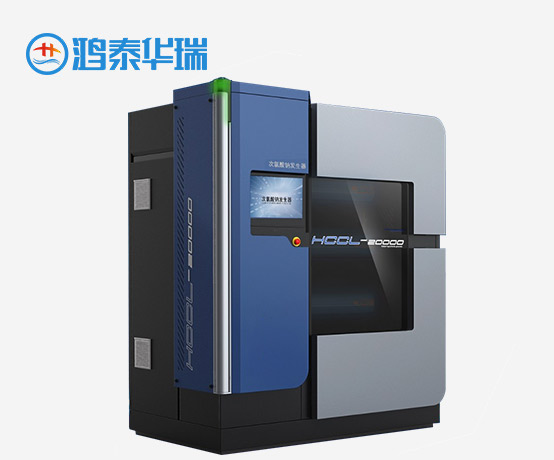

Combined with our country's actual business development, the technologies widely used in China for the problem of zero discharge of high-salinity wastewater mainly include RO reverse osmosis membrane double membrane method and EDR technology, the main material is nano-scale reverse osmosis membrane, which is very effective for heavy metal ions and many organic matter. Under the normative pressure, water can be finally constructed into a permeable membrane that can decompose inorganics, heavy metal ions, macromolecular organic matter, colloids, and bacteria including viruses to rationally avoid and block value. However, with the advancement of technology and the improvement of research level, the emergence of MVR technology has improved the overall efficiency, not only in terms of floor area is much smaller than that of space, but also very simple in structure, and the energy-saving effect is very prominent. In terms of technical principle, it is basically combined with the compressor to compress the steam at the low temperature level, increase its thermal enthalpy, and fully excite the latent heat of the steam to achieve the actual required effect. There is no need to activate the various types of devices here.

2.2 Research on the influencing factors and treatment of MVR technology performance

The material performance of MVR technology in the recovery and harmless treatment of high-salinity wastewater resources mainly includes the following aspects. In the actual parameters, there are mainly density and strength, melting point, heat sensitivity, hardness, viscosity, etc., its main heat transfer coefficient depends on the area occupied by evaporation, surface tension is mainly to promote the surface shrinkage pressure of the liquid, the values in the process of vapor-liquid separation, such as height and diameter are also very direct and specific influencing factors, and also have a direct impact on the material on the membrane; In addition, for all kinds of materials with very high boiling points, single-effect evaporation can also be adopted to reduce the overall temperature under negative pressure and save actual operating costs. You must also pay enough attention to the requirements for the temperature.

In the actual operation of the facility, attention should be paid to the change of feeding parameters. Because the law of conservation of energy in physics is standardized, the maximum value that the device can propagate is fixed, so it is necessary to consider this problem when feeding. The actual concentration of high-salinity wastewater also needs to be paid attention to, which is directly related to the heat transfer coefficient and the actual boiling point. If the temperature of the high-salinity wastewater entering the plant is very low, it can also cause a significant reduction in evaporation.

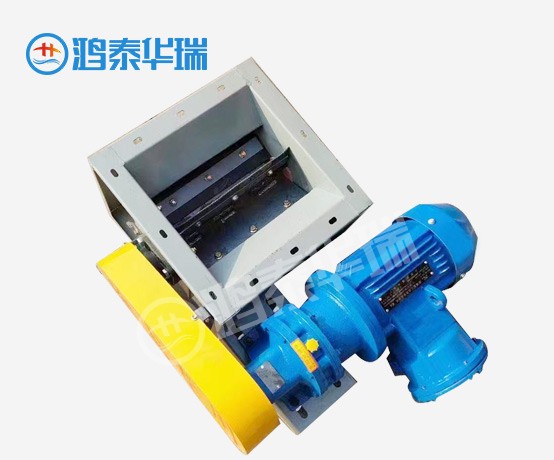

Secondly, pay attention to the changes in the working conditions of the MVR compressor. The compressor has the highest values for flow, temperature, pressure ratio, efficiency and other parameters, which have a very direct impact on the actual operation of the overall device. For example, in all kinds of high-salinity wastewater treatment, if the inlet temperature is low and the specific volume increase is large, the compressor can enter a lot of steam, and the inlet temperature will also increase a lot, so it must be paid attention to in practical problems. The actual frequency and flow rate of the compressor, as well as the value of the temperature rise, can be rated, so enough water can be evaporated at a lower temperature difference, and if the treatment point temperature is all kinds of high-salt wastewater, the compressor needs to overcome the existing problems before it can evaporate.

On the separator, it is necessary to pay attention to the increase in the evaporation of high-salt wastewater, which leads to the acceleration of the rise of secondary vapor, and will also make the gas carry a large amount of liquid, and if the time is too long, it will lead to the destruction of the equilibrium temperature. The secondary steam volume of the MVR steam system will increase a lot in the stability of the flash steam, the specific volume of the secondary steam is relatively large, and the material concentration and viscosity tension will increase a lot, so the diameter ratio needs to ensure the separation of gas and liquid, and there is enough separation surface, and the height and cost will also have a practical impact. Attention should be paid to the recovery of high-salt wastewater resources.

In addition, the pump will also have an impact. As the main power unit, mechanical density, actual operating flow, and height will have a direct impact and constraint on the whole. Therefore, it is necessary to pay attention to the sealing degree and try to avoid all kinds of leakage.

2.3 Research on the performance of MVR technology in the treatment of high-salt wastewater

For a certain evaporation MVR system, the corresponding evaporation area and preheating area of the system will first decrease and then gradually appear flattened in the treatment of high-salt wastewater, and in the actual work of relatively large evaporation, it will look very significant as a whole. In addition, the specific power consumption of the compressor also has a relatively direct impact on the temperature. Therefore, it is best to keep the material temperature difference at 4 degrees, that is, the power consumption is below 20 kWh per cubic meter.

The actual range of the traditional temperature difference is about 1-10 degrees, with the gradual increase of the heat transfer temperature difference, all the evaporation area will be sharply reduced and then march smoothly, for the working condition of about 70 °, the increase of three degrees will lead to a decrease of about 1000 square meters in the overall heat transfer area, but in the actual situation of temperature rise, the overall heat transfer area will also gradually decrease. Combined with the author's actual research, it is a reasonable range to maintain 3-7 degrees, which is the most beneficial for the overall business promotion and development.

In terms of feed and discharge concentration, the area held by evaporation will decrease linearly with the increase of feed concentration and increase linearly with the increase of discharge concentration, which will be more significant at relatively low temperatures. For the concentration of the feed material, the specific power consumption of the compressor will gradually increase with the increase of the feed concentration, but the effect on the discharge is not large.

In addition, under certain heat transfer conditions, the evaporation temperature has a relatively low effect on the evaporation area of the system, but the area decreases with the increase of temperature.

3. Conclusion

On the whole, for the evaporation process of high-salt wastewater, the heat transfer temperature difference is the main factor affecting the evaporation area and compressor power consumption. Relatively low material concentration and relatively high discharge value concentration require a relatively large evaporation area, so it needs to be controlled.