Chemical industrial parks are key drivers of industrial economic growth, but wastewater treatment, especially for oil-containing wastewater, remains an inescapable environmental challenge. Many parks face similar difficulties: wastewater containing floating oil, emulsified oil, and dissolved oil, mixed with toxic and hard-to-degrade substances such as phenols and cyanides. Water quality fluctuations are so severe that treatment systems frequently experience "pressure." For example, petrochemical industry wastewater can exceed 1000 mg/L in oil content, while fine chemical wastewater often has poor biodegradability, with BOD5/COD ratios below 0.2. Coal chemical wastewater presents a "dual threat" with high salt and high toxicity, with salt levels reaching up to 50,000 mg/L.

Stricter environmental regulations and the dual carbon goals have added further complexity to the treatment challenge. Nowadays, wastewater discharge standards not only require COD ≤ 60 mg/L and oil content ≤ 5 mg/L, but in some areas, emerging pollutants like PFOA and PFOS must be "non-detectable." At the same time, land scarcity, high operational costs, and low resource recovery rates make it increasingly difficult for traditional treatment processes to meet the "high-efficiency, low-carbon, and resource-recycling" demands.

To tackle these challenges, the key lies not in simply stacking individual technologies, but in designing a comprehensive treatment system that aligns with the specific water quality characteristics of the park. The process—from pollution control at the source to deep reuse—must be designed with efficiency, stability, and energy savings in mind, ensuring that the treatment process is both scientifically sound and practical to implement.

Let’s start with the source pretreatment, which serves as the "first line of defense." The core objective is to quickly "lighten the load" by separating floating oil and suspended solids, and disrupting stubborn emulsions to clear the path for subsequent treatments. For high-oil-content wastewater, the combination of "inclined plate oil separation + flotation" has been proven effective in practice. The inclined plate separator increases the separation area, allowing floating oil droplets larger than 150 μm to quickly aggregate and float up, achieving oil removal rates of over 85%. Paired with a vacuum oil skimmer, over 90% of floating oil can be recovered for reuse. The subsequent flotation system—whether a vortex flotation or dissolved air flotation—generates microbubbles (50-100 μm) that act as "handles" to adsorb small emulsified oil droplets and suspended solids. With the addition of a demulsifier, oil removal rates can reach 85%-96%, reducing the oil content of the effluent to below 30 mg/L.

For severely emulsified fine chemical wastewater, an additional demulsification step is necessary. This can be achieved using nano-demulsifiers, which require only one-fifth the amount of traditional agents and can achieve oil removal rates above 95%. Alternatively, electro-demulsification technology can be employed, which uses a low-voltage, high-frequency pulse magnetic field to alter the oil-water interfacial tension, completing demulsification in just 50 seconds without additional chemical additives, thus avoiding secondary pollution. Proper pretreatment ensures that the subsequent biological system is less impacted, improving stability.

Once pretreatment is completed, the focus shifts to the core degradation process, where the goal is to "break the deadlock"—removing difficult-to-degrade organic compounds and eliminating nitrogen and phosphorus to continuously improve water quality. For wastewater with poor biodegradability, it cannot directly enter the biological treatment system and needs to undergo an advanced oxidation process to "clear the way." Fenton oxidation uses Fe²⁺ and H₂O₂ to generate hydroxyl radicals, which effectively degrade difficult organic compounds such as aromatics and heterocyclics. Ozone catalytic oxidation, coupled with ultraviolet light, can rapidly break down dissolved oils and toxic pollutants without generating secondary pollution, making it ideal for high-salinity wastewater scenarios.

Biological treatment processes should be chosen based on the park's size and water quality needs. Large petrochemical parks are suited for the A²/O process, which integrates "anaerobic phosphorus release, anoxic denitrification, and aerobic phosphorus uptake and degradation," achieving a COD removal rate ≥ 85% and ammonia nitrogen removal rate ≥ 90%. For parks with limited land or smaller projects, MBR (Membrane Bioreactor) technology is more appropriate. MBR combines activated sludge and membrane filtration, achieving high sludge concentrations (8000-10,000 mg/L), strong resistance to shock loading, a COD removal rate of over 92%, and even reducing the oil content in effluent to below 1 mg/L, all while preventing common issues like sludge bulking in traditional systems.

For coal chemical wastewater with strong biological toxicity, additional biological enhancement technologies should be introduced. This may include the use of high-efficiency degrading microbial agents or genetically engineered bacteria, which can increase the degradation rate of toxic substances such as phenols and cyanides by over 40%. New carrier materials like bio-carbon fibers can provide more attachment sites for microorganisms, forming high-activity biofilms that further strengthen the degradation effect.

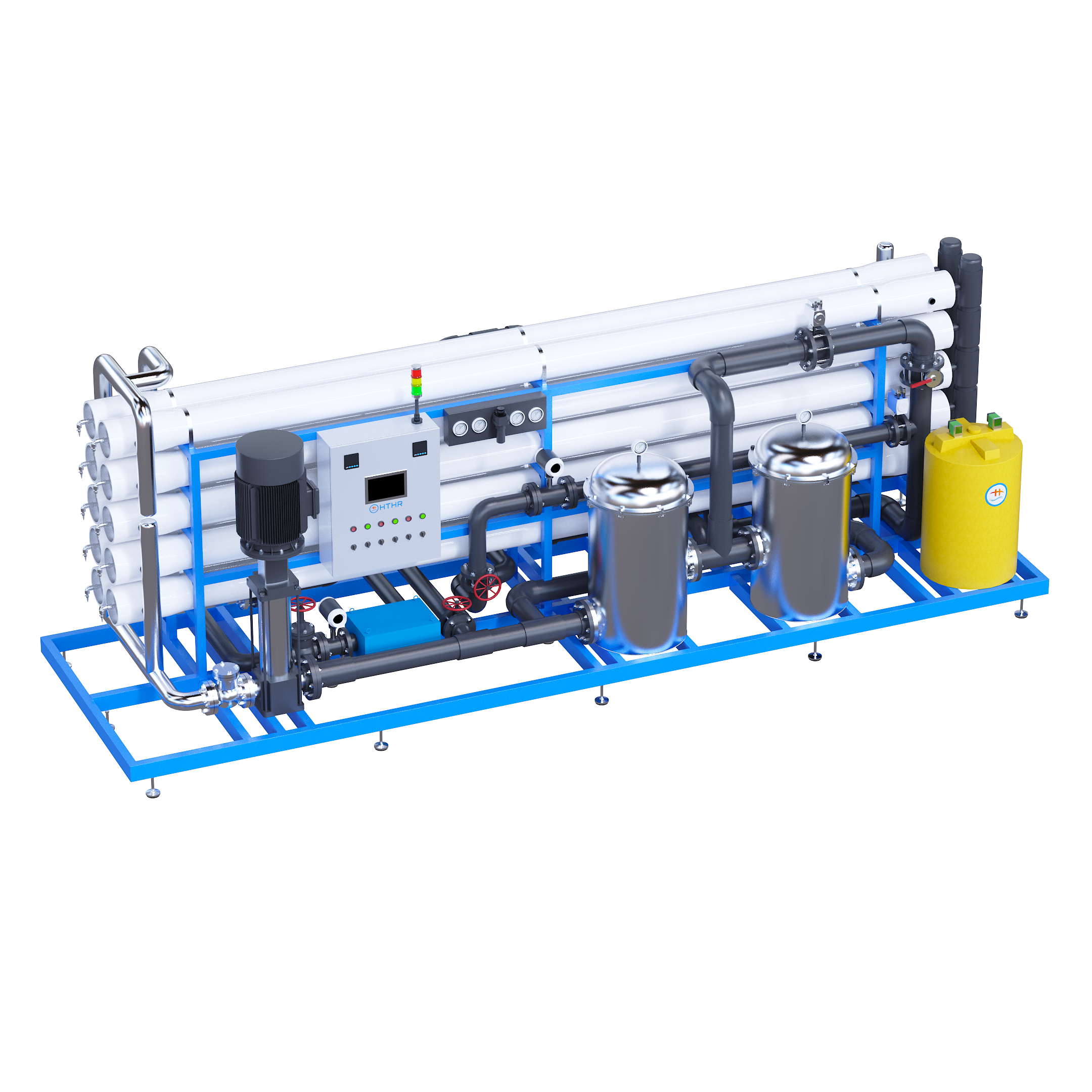

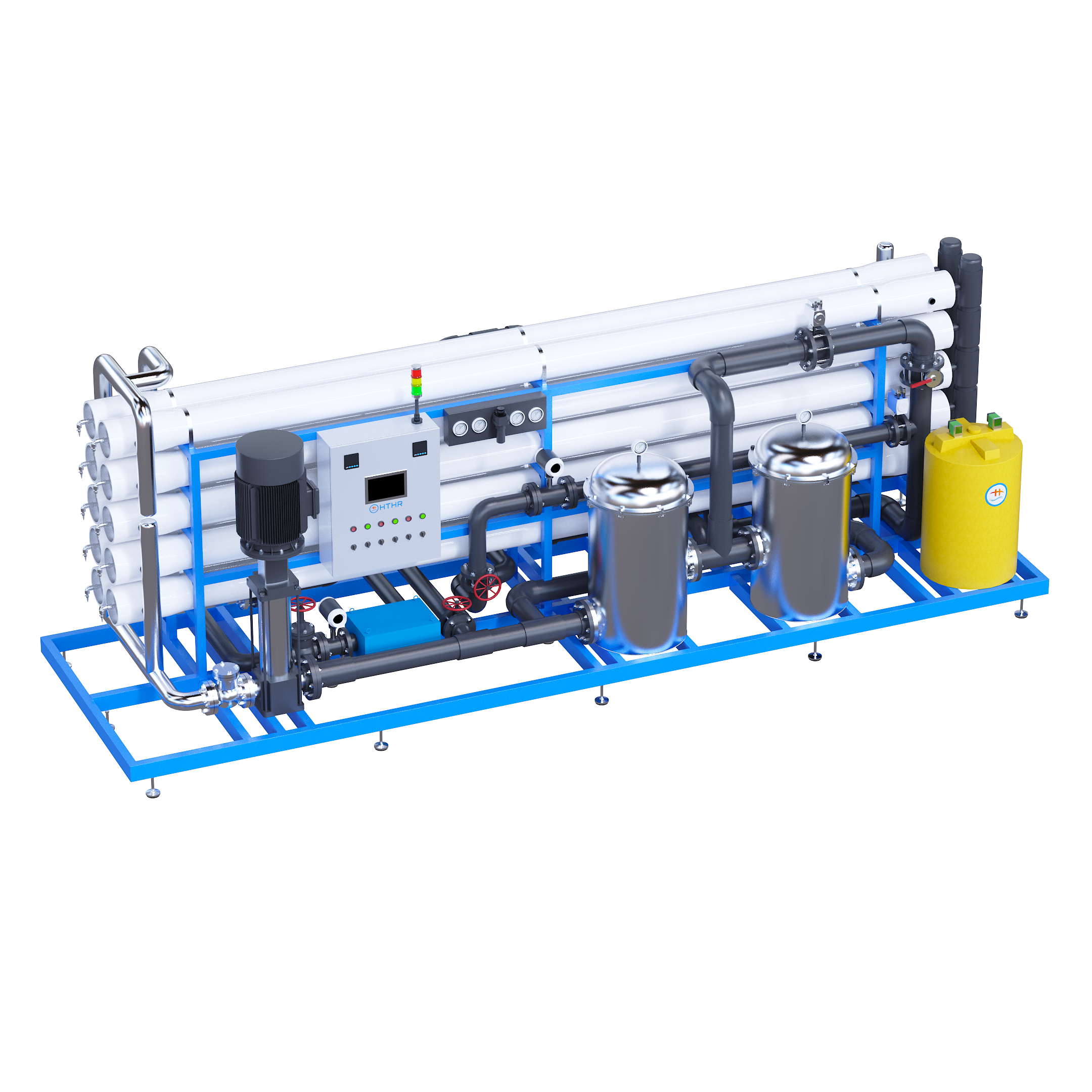

With the dual carbon goals and water conservation demands driving the need for deeper treatment and reuse, these processes have become "must-haves" rather than "optional." The focus here is on "quality improvement + recovery," transforming wastewater from a "pollutant" into a "reusable resource." Common combined processes include "advanced oxidation + filtration + desalination": ozone catalytic oxidation or Fenton oxidation breaks down residual difficult-to-degrade organic compounds, fiber ball filtration captures fine suspended solids (with filtration precision up to 99.99%), and reverse osmosis (RO) membranes desalinate residual salts, resulting in effluent that meets standards for recycled water or boiler make-up water.

Resource recovery is another essential factor. After purification, recovered floating oil can be refined and reused, reducing raw material losses. Post-treatment effluent can be reused within the park for irrigation, equipment cleaning, or production cycles, achieving a reuse rate of over 60%. Biogas produced during biological treatment can be purified and used for power generation or heating, achieving energy self-sufficiency and reducing operational energy consumption. The parallel efforts of treatment and recovery can truly realize both environmental protection and economic benefits.

The success of an efficient treatment process relies on scientific equipment configuration. Equipment selection should not be about "the more expensive, the better," but should adhere to the principles of "adaptability, cost-effectiveness, reliability, and intelligence," aligning with the park's treatment scale, water quality characteristics, and site conditions. For example, for pretreatment equipment, integrated and skid-mounted products are preferred: inclined plate oil separators with automatic oil scraping and heating devices prevent oil solidification and clogging in low temperatures. In flotation systems, high-efficiency dissolved air flotation tanks with advanced gas release devices can achieve a bubble concentration of 10⁷ per mL, improving separation efficiency by up to 100 times compared to traditional systems.

Core treatment equipment selection should focus on "efficiency and stability." MBR membrane components are recommended to be made from hydrophilic modified PVDF or PTFE materials, with pore sizes of 0.1-0.4 μm, offering strong anti-pollution capacity and a lifespan of 5-8 years. Advanced oxidation equipment should be selected according to needs, with Fenton reactors equipped with precise dosing systems, and ozone generators with high-efficiency catalytic fillers to enhance oxidation efficiency while reducing energy consumption. For deep treatment equipment, fiber ball filters made with modified polyester filter materials are hydrophilic and oleophilic, with good backwashing regeneration properties and effluent turbidity of ≤3 FTU. Reverse osmosis membranes should be paired with high-pressure pumps and energy recovery devices to reduce energy consumption by more than 20% per ton of water.

In today's chemical industry wastewater treatment, intelligence is a core trend and key to improving efficiency and reducing costs. Through an integrated system of "online monitoring + PLC control + remote management," precise process control and efficient operation can be achieved. Equipment integrates online monitoring instruments for pH, DO, COD, oil content, etc., collecting key process parameters in real time and transmitting data to a PLC control system. Based on preset logic, the system automatically adjusts chemical dosing, aeration rates, and oil scraping frequencies. If water quality fluctuates beyond set thresholds, it triggers alarms and activates emergency measures to protect the system from being overwhelmed.

To further enhance operational efficiency, digital twin and AI optimization technologies can be introduced. A virtual model of the equipment is built to simulate its operating conditions under different scenarios, optimizing maintenance strategies in advance. AI algorithms can also learn from water quality fluctuations and dynamically adjust operational parameters. For example, in the case of the Shengli Oilfield, after an intelligent upgrade, treatment efficiency increased by 140%, and energy consumption per ton of water decreased by 15%-20%. Managers can remotely monitor equipment status, water quality data, and issue operational instructions through computers or mobile terminals, enabling cross-regional centralized management and reducing manual intervention.

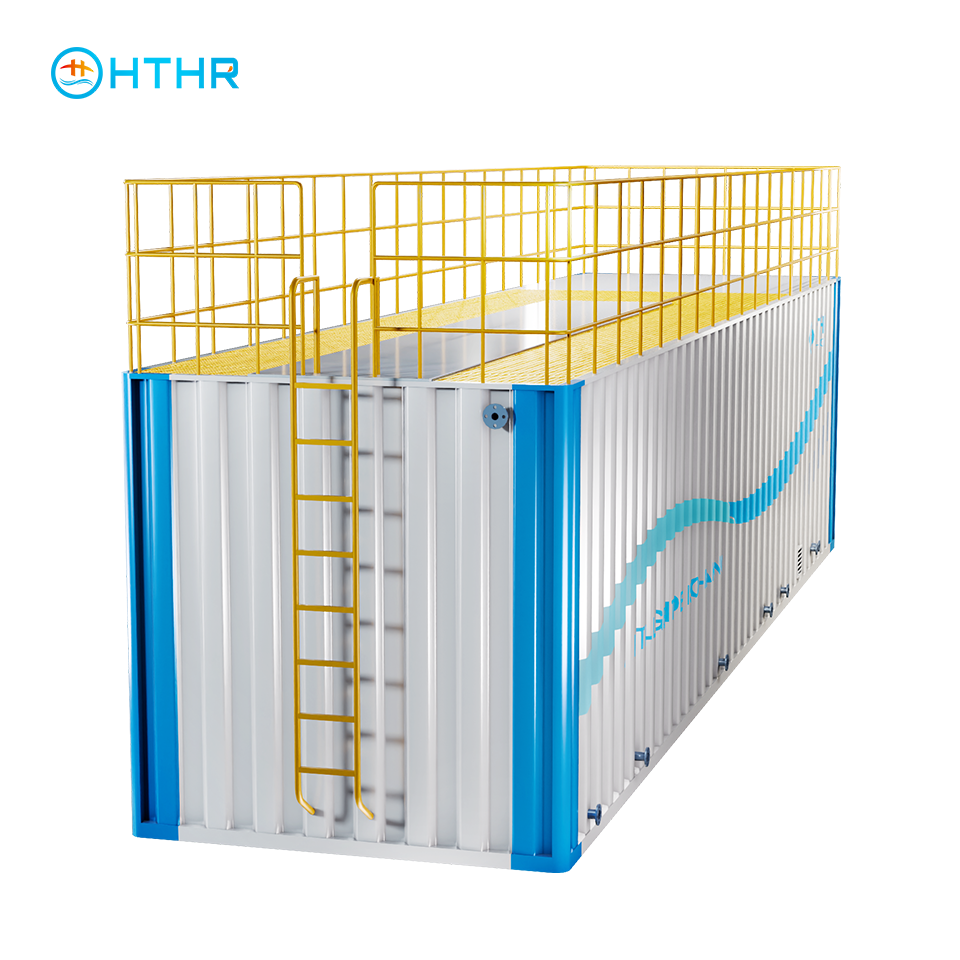

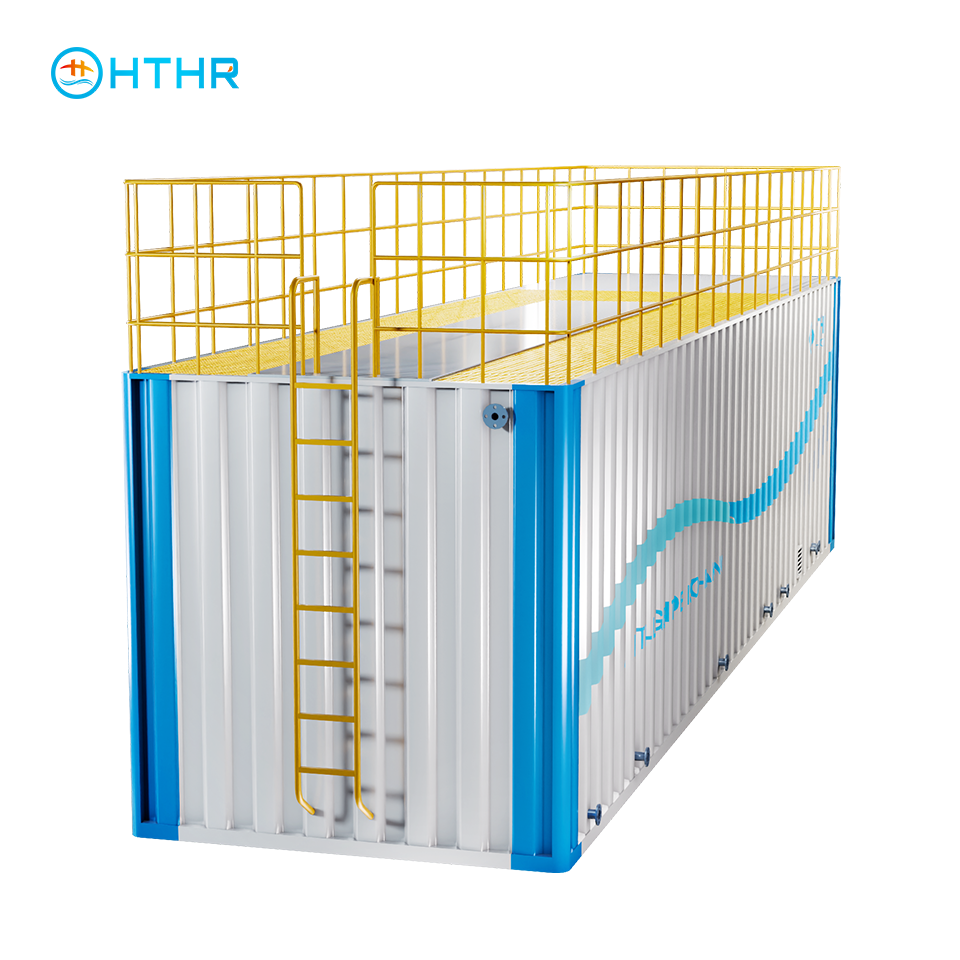

For parks with limited space, equipment space optimization is also crucial. Skid-mounted and modular equipment design offers clear advantages. For example, integrated oil wastewater treatment devices, which combine oil separation, flotation, filtration, and disinfection in a single unit, occupy only one-third the area of traditional concrete treatment plants and can be constructed in just three months. In terms of energy optimization, the aeration system uses high-efficiency energy-saving aerators with variable-frequency control. When coupled with sewage-source heat pumps and photovoltaic-driven systems, waste heat recovery and clean energy utilization can reduce the carbon footprint of water treatment units by over 50%, supporting parks in achieving dual carbon goals.

The rationality of these process designs and equipment configurations has long been verified by successful practices in numerous chemical industrial parks at home and abroad. PetroChina Lanzhou Petrochemical’s 1080 t/h oil refinery wastewater deep treatment and reuse project adopts the “flotation + aerated biofilter + ultrafiltration + reverse osmosis” process, combined with intelligent management and control equipment, and the effluent meets the boiler make-up water standard. It can save 8 million tons of fresh water and reduce wastewater discharge by 6.5 million tons annually; Sinopec Yangzi Petrochemical selects multi-stage integrated fully enclosed oil-water separation equipment, replacing traditional processes with “classified treatment and dedicated line purification,” without adding chemical agents and no secondary pollution. Its 200 t/h high-oil-content wastewater treatment capacity provides replicable experience for source pollution control in refining and chemical enterprises.

International cases are also very valuable for reference. A European chemical industrial park has realized intelligent regulation of the entire wastewater treatment process through the integration of digital twin technology and biological treatment technology, with a water reuse rate of over 60% and energy consumption 25% lower than traditional processes; a domestic high-tech petrochemical industrial park adopts a complete process of “pretreatment + hydrolysis acidification + A²O-MBR + ozone catalytic oxidation + aerated biofilter,” combined with high-efficiency membrane modules and intelligent control systems. After long-term stable operation, the effluent quality meets the Class A standard of GB 18918–2002, perfectly solving the problem of mixed wastewater treatment from multiple industries.

Looking ahead, with the continuous tightening of environmental policies and the continuous iteration of technologies, chemical industrial park oil-containing wastewater treatment will surely develop in the direction of “higher efficiency, more energy conservation, smarter, and more circular.” Technically, cutting-edge technologies such as microbial fuel cells, photovoltaic-driven water treatment systems, and AI optimization control will be applied on a large scale to realize the integration of “pollution control + energy conservation + power generation”; in terms of equipment, modular, skid-mounted, high pollution resistance, and long-life products will become mainstream, and the level of intelligence and energy consumption optimization will continue to improve.

For chemical industrial parks, the core of the future treatment path is to build an integrated solution of “classified diversion + precise treatment + resource recycling” in combination with their own industrial characteristics. It is necessary not only to achieve wastewater discharge up to standard and resource reuse through scientific process design and equipment configuration, but also to strengthen industry-university-research cooperation and introduce cutting-edge technologies to promote system upgrading; more importantly, rely on intelligent management and control platforms to improve operational efficiency, reduce operational costs, and practice the concept of low-carbon development.

The treatment of oil-containing wastewater in chemical industrial parks has never been a simple environmental protection task, but also an important opportunity for industrial upgrading. When efficient treatment processes are deeply integrated with scientific equipment configuration, it can not only solve the problem of water pollution control, but also realize the recycling of water resources and energy, injecting core power into the high-quality and sustainable development of parks. In the future, we will continue to deepen our focus on the field of chemical wastewater treatment, focus on technological innovation and equipment upgrading, provide more demand-oriented, efficient and energy-saving oil-containing wastewater treatment solutions for global chemical industrial parks, and work together with parks to build a new pattern of green ecological development.

hthrjt2017@gmail.com

hthrjt2017@gmail.com