MBR membrane bioreactor vs. traditional activated sludge process: Which is more suitable for your project?

- release date: 2026-01-13 13:44:45

- author: Hongtai Huairui

- Reading: 771

- key words: MBR membrane bioreactor、traditional activated sludge process

Against the background of the intensifying global water crisis, the extreme water shortage and high temperature environment in the Middle East, the violent fluctuations in water quality and quantity in Southeast Asia and the scattered treatment needs have made the choice of sewage treatment technology the key to the success or failure of the project. When MBR membrane bioreactor and traditional activated sludge process compete on the same stage, how can we accurately match the needs of our own projects?

Focusing on the core pain points of the Middle East and Southeast Asian markets, the difference in adaptability between the two technologies is particularly significant: for the Middle East, the reality that per capita water resources are less than 500 cubic meters per year makes sewage reuse a rigid demand.

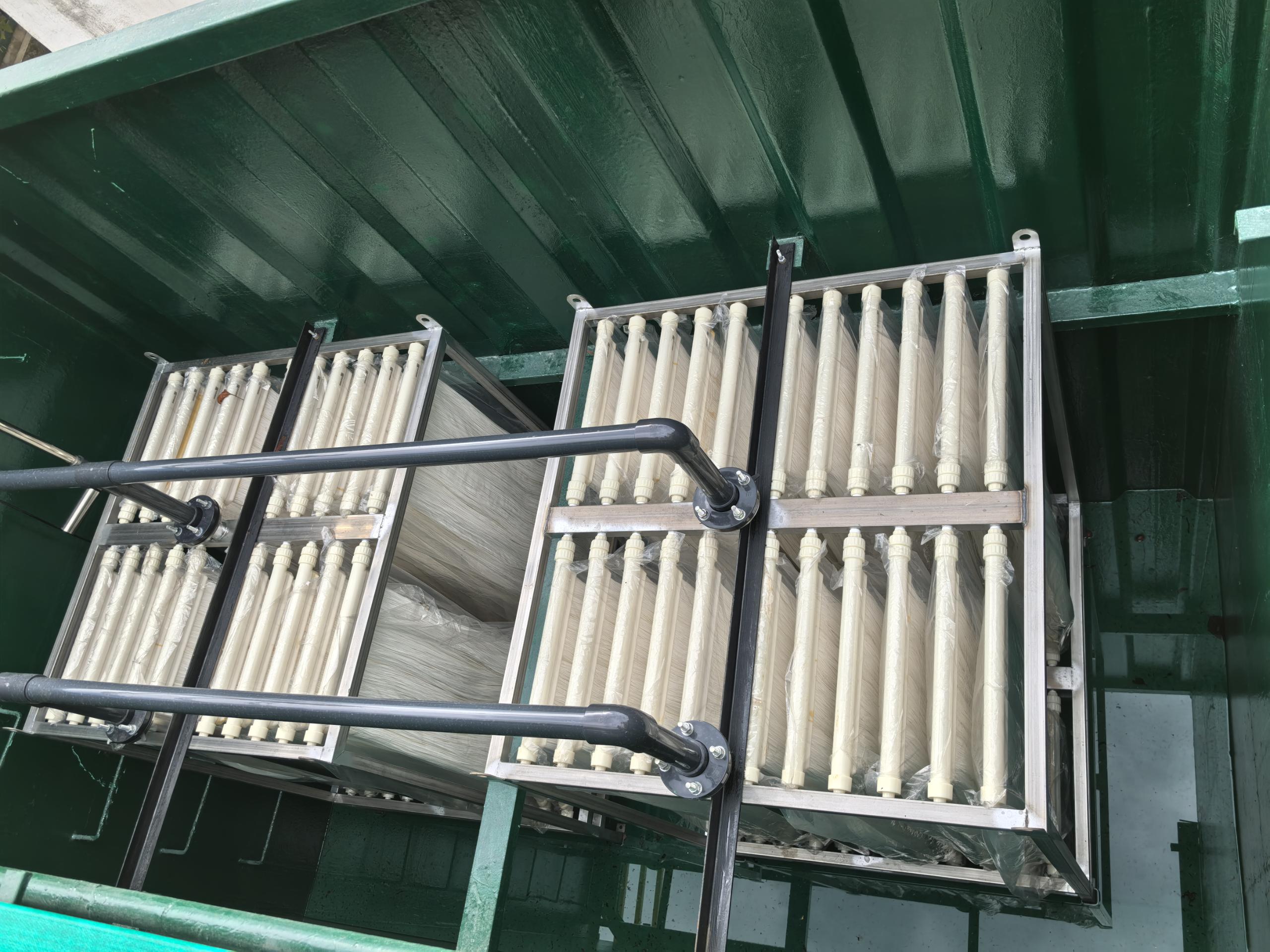

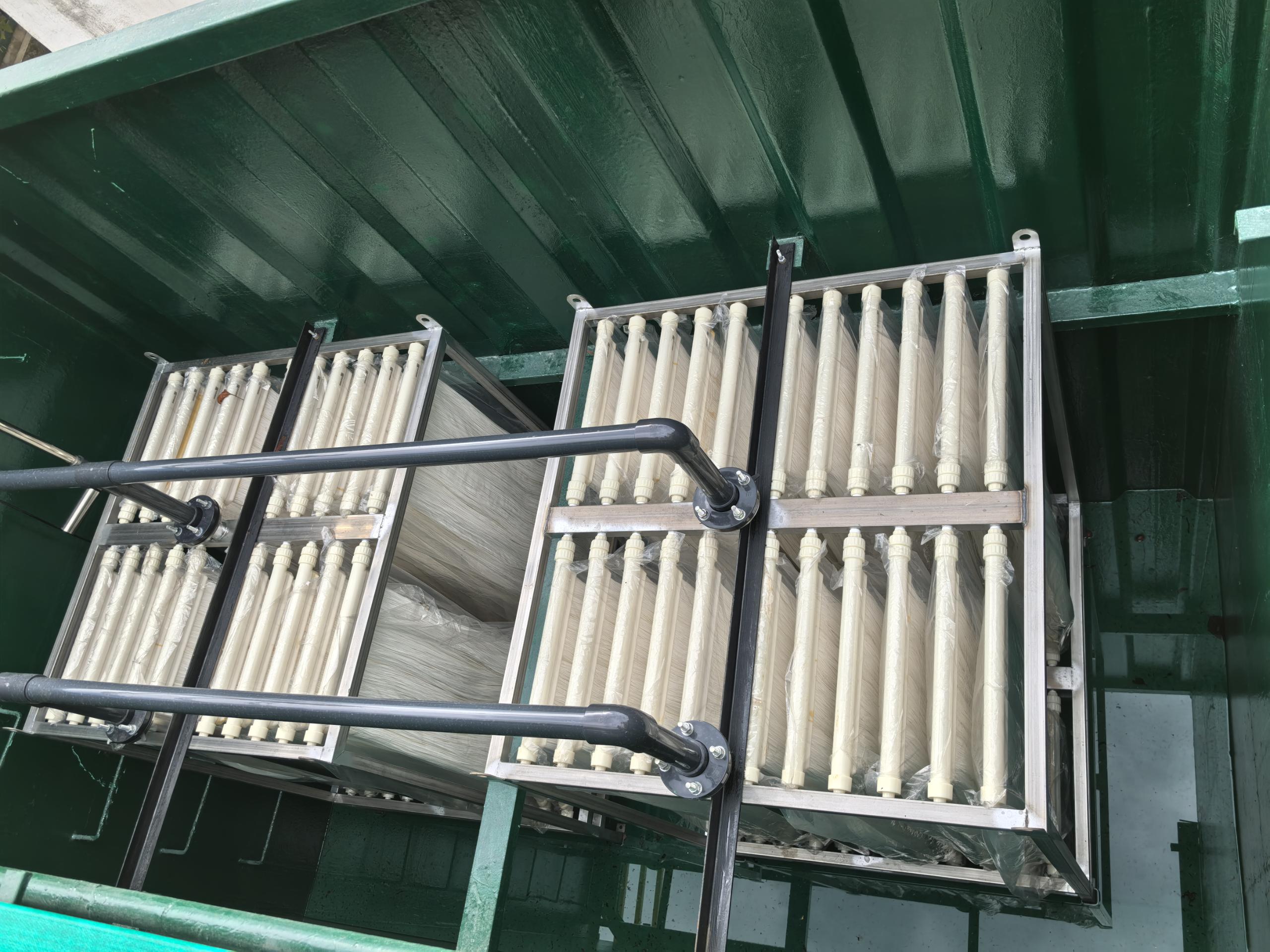

MBR technology relies on the advantages of precision filtration of 0.1-0.4 m, SS 5mg/L and BOD 10mg/L of effluent water, which can directly meet the reuse standards of agricultural irrigation and industrial cooling, which perfectly meets the goal of 95% reuse rate of United Arab Emirates 2036 water safety strategy. At the same time, its 30-50% land saving rate is extremely advantageous in urban land-intensive areas such as Dubai and Doha, and can better adapt to stable operation in high temperature environments above 40 ° C. In contrast, the effluent quality of traditional activated sludge processes fluctuates greatly, and additional three-level treatment units are needed to meet the standards for reuse. Its competitiveness in the Middle East market where land resources are precious is limited. In Southeast Asia, water quality fluctuations in the rainy season can reach 3-5 times the dry season, and the need for decentralized treatment in many islands and rural areas test the impact resistance and flexibility of technology.

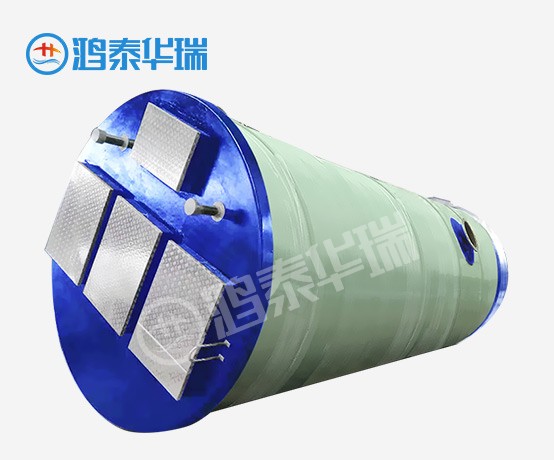

MBR's high sludge concentration (8-12g/L) design makes its impact load resistance far superior to traditional activated sludge processes (MLSS is only 2- 4 g/L). Even in the face of complex conditions such as heavy rain peaks or industrial wastewater mixing, it can also ensure the stability of effluent. Its modular architecture is more suitable for the rapid deployment of decentralized projects such as Indonesia and the Philippines, significantly reducing the cost of pipe network construction. Although the traditional activated sludge method is mature in technology and low in initial investment, it is prone to sludge loss in scenarios with large fluctuations in water quality, and it occupies a huge area, making it difficult to adapt to the needs of high-density Urban area and scattered sites.

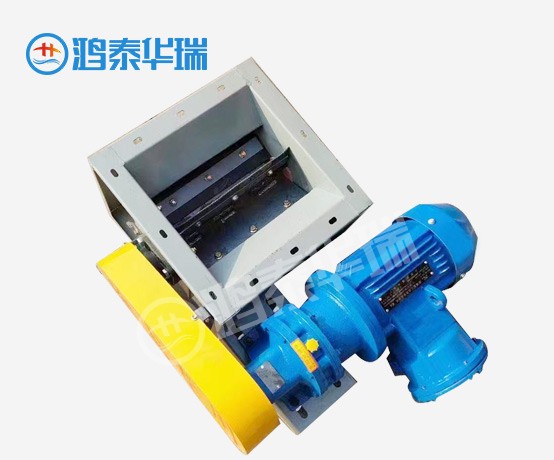

From an economic perspective, although the initial investment of MBR is higher than that of traditional processes, the cost advantage of the full life cycle is significant. In the Middle East, its sludge production is reduced by 30-50%, which can significantly reduce the high local sludge disposal costs (US$50 -80/ton); in Southeast Asia, low drug consumption and automated operation and maintenance characteristics can effectively offset the problem of high local pharmaceutical procurement costs and shortage of professional operation and maintenance personnel. Hongtai Huarui Technology Group is deeply involved in the field of environmental protection and intelligence. It has customized MBR solutions for the Middle East and Southeast Asian markets. It also optimizes energy consumption per ton of water to 0.4-0.6kWh/m³ through precise aeration control and intelligent operation and maintenance systems., further amplifying the cost advantage.

So, how to make the final choice? The core is to anchor the core requirements of the project: If your project is located in the Middle East and has clear reuse needs, limited land area or faces strict nitrogen and phosphorus emission standards, MBR is undoubtedly a better solution; if it is a small municipal project with limited budgets in Southeast Asia, and only needs to meet basic emission requirements, traditional activated sludge methods can be used as a transition option. If long-term stable compliance and cost reduction and efficiency increase are pursued, the technological foresight and adaptability of MBR are even more worth looking forward to.

From the MBR reuse practice of the NEWater project in Singapore to the high-temperature and stable operation of the Al-Ansab sewage treatment plant in Muscat, Oman, the implementation of advanced technologies has always been inseparable from localized adaptation and optimization. With its in-depth insight into the Middle East and Southeast Asian markets, Hongtai Huarui can provide a full chain of services from technology selection, customized design to intelligent operation and maintenance, helping projects accurately match technical solutions and achieve a win-win situation between sustainable use of water resources and economic benefits.

Want to get a technical selection solution exclusive to your project? Welcome to contact us to unlock targeted solutions!

hthrjt2017@gmail.com

hthrjt2017@gmail.com