- release date: 2022-08-16 01:08:00

- author: Hongtai Huairui

- Reading: 4896

key words: Guangxi, sugar production, circulating cooling water

Hongtai Huarui Technology Group welcomes your visit. We have been dedicated to the environmental protection and governance industry for over a decade! We look forward to a cooperation with you!

key words: Guangxi, sugar production, circulating cooling water

project overview

The sugar making enterprise is located in Qinzhou City, Guangxi Zhuang Autonomous Region. Its main business is the production and sales of sugarcane sugar and sugar syrup, and the deep processing of sugar. The enterprise mainly uses the sulfurous acid method to make sugar, which has the advantages of mature and reliable process, simple process and equipment. The entire sugar production process can be divided into several processes: squeezing, clarifying, hair removal, sugar boiling, densifying and drying and packaging.

The wastewater from this project is the circulating cooling discharge water during the refining process. It is the discharge water after exchanging medium heat through heat exchange or direct contact heat exchange and being cooled by a cooling tower. The company's circulating cooling water discharge is 8400m3/d. The design adopts a combined treatment process of "water collection well + hydrolysis acidification tank + biological contact oxidation tank + secondary sedimentation tank. The effluent water quality meets the" Comprehensive Sewage Discharge Standard "(GB8978-1996). Level one discharge standard. The wastewater treatment project covers an area of approximately 1183m2, the total installed capacity of the system is 257kW, and the operating cost is approximately 0.24 yuan/m3wastewater (excluding depreciation).

Design basis

(1) "Comprehensive Sewage Discharge Standard" (GB8978-1996);

(2) Various relevant basic information provided by the builder (water quality, water quantity, discharge requirements, etc.);

(3) "Technical Conditions for Water Treatment Equipment" (JB/T2932-1999);

(4) On-site survey data:

(5) Relevant sugar industry wastewater treatment standards and information:

(6) The spirit of relevant national, provincial and regional laws, regulations and documents;

(7) Other relevant design codes and standards.

Design principles

(1) Conscientiously implement the national guidelines and policies on environmental protection, so that the design complies with relevant national regulations, norms and standards:

(2) Comprehensively considering the characteristics of wastewater quality and quantity, the treatment process should be technologically advanced, reliable and reliable, economically reasonable, flexible and safe to use:

(3) Properly treat and dispose of sludge and scum generated during wastewater treatment to avoid secondary pollution:

(4) The automatic control system of the wastewater treatment system should be convenient to manage, safe, reliable, economical and practical

(5) The layout of the wastewater treatment system should strive to be compact, reduce land occupation and investment, and the elevation layout should adopt a three-dimensional layout as much as possible. Make full use of underground space;

(6) Properly consider the development prospects of the enterprise and leave room for design;

(7) Design in strict accordance with the defined conditions of the construction party to adapt to the actual situation of the project.

Source of pollution

For the circulation of cooling discharge water in the refining process, it is the discharge water after exchanging medium heat and cooling by cooling tower by heat exchange or direct contact heat exchange

Processing technology

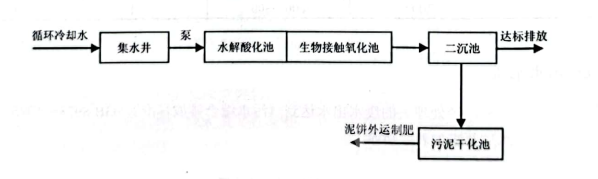

Considering the specific conditions of the water quality and quantity of the circulating cooling water discharged by the sugar enterprise, the design adopts the process of "water collection well + hydrolysis acidification tank + biological contact oxidation tank + secondary sedimentation tank", and the specific process flow is shown in Figure 1.

Fig. 1 Wastewater treatment process

4.3 Description of the process flow

This treatment process is divided into three major systems, namely pretreatment system, biochemical treatment system and sludge treatment system.

Handling indicators

According to the information provided by the builder, the total amount of wastewater designed is 8,400m3/d, the average processing capacity is 350m based on 24 hours of operation per day3/h.

The design wastewater influent water quality index is shown in Table 1.

Table 1 Design wastewater influent water quality

|

project |

BOD5/ (mg/L) |

CODCR/(mg/L) |

SS /(mg/L) |

pH |

|

Influent water quality |

300 |

600-800 |

21 |

6.0~9.0 |

According to the requirements of the construction party, the treated wastewater effluent meets the first-level standard in the "Comprehensive Sewage Discharge Standard" (GB8978-1996), and the specific effluent water quality requirements are shown in Table 2.

Table 2 Design wastewater effluent quality

|

project |

BOD5/ (mg/L) |

CODCR/(mg/L) |

SS /(mg/L) |

pH |

|

The quality of the effluent |

≤20 |

≤100 |

≤20 |

6.0~9.0 |

Previous Article:Printing and dyeing wastewater reuse and...

Next Article:Breeding wastewater treatment and reclai...

The content you might be interested in

Environmental Protection Information

Selected Recommendations

Recommended Products