Our company's painting workshop found that there were visible particles and fibers on the car body during the process of blowing and cleaning the topcoat, and after the blowing and polishing treatment before the topcoat, it was found that there were still particles in the topcoat inspection and polishing line, and the line grinding operation must be stopped. Combined with the on-site process layout, it is found that because the output of the model is small, affected by the aging of the electrophoretic paint, the overall body electrophoretic polishing points are more numerous, and there is a transportation storage space with a length of about 176 m between electrophoretic polishing and the topcoat is blown clean. Therefore, in order to ensure the cleanliness of the body, improve the quality of body spraying, and improve the production process related to later inspection and refinement, it is planned to add a hoisted dry atomization humidifier for dust removal on site, reduce static electricity by increasing relative humidity, reduce the adsorption capacity of the body to dust, improve the quality of the body, eliminate particle defects, and increase the pass rate by more than 50%.

1 Principle and characteristics of atomization humidification and dust removal

1.1 Atomization humidification and dust removal principle

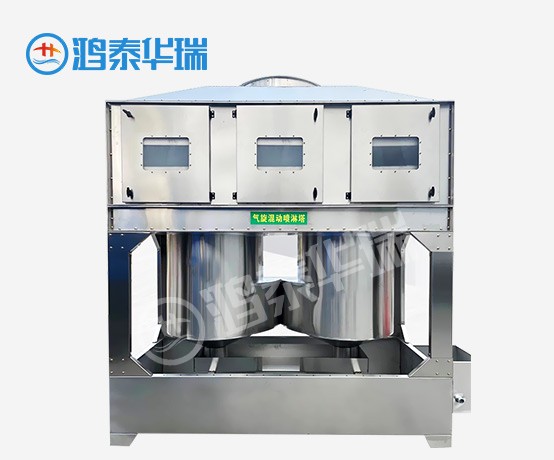

Atomization humidification spraying refers to mixing water and air under the action of pressure and delivering it to the mist generator, and then spraying it out from the sprinkler to produce water mist. The particle size of this water mist is very small, ≤ 7.5 μm ultrafine mist particles are sprayed into the entire space, floating in the air for a long time to achieve the effect of humidifying the surrounding air. Spray humidification not only plays a role in humidifying the surrounding air atmosphere, but also plays a certain role in cooling, anti-static (increasing ambient humidity, reducing static electricity), dust removal, dust reduction, dust suppression, etc., Figure 1 shows the effect of the introduction of the humidification system on static electricity. Usually when the relative humidity > 60%, the charge of dust particles will drop sharply, so the relative humidity of the paint booth is (65±5)%, and the temperature is (23±2) °C.

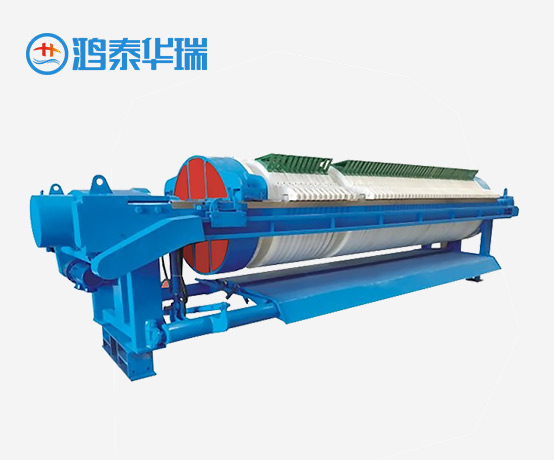

The dust particle size as a settling object is generally between 0.01~100 μm, and the dust particles above 100 μm can quickly land under the action of gravity and cannot become the dust removal object, while the dust particles of 3 ~ 8 μm can float in the air with the air flow due to their small mass, and it is extremely difficult to separate. The dry mist humidification spray head will spray water mist ≤ 7.5 μm, and the water mist with small particle size is very easy to capture the particles in the air, and with the increase of time, the captured particles will naturally fall and settle due to the increase of mass. Smaller particles will also gradually settle due to adherence to water vapor, eventually achieving the effect of complete dust removal. The following introduces a common atomization humidification spraying system (see Figure 2), which mainly consists of: water atomization generator, control unit, installation component part, water vapor pipeline, humidity control unit, and filtration equipment.

When actually designing products and process planning, they can be appropriately adjusted according to factors such as cost budget and site size. For example, if the overall ambient temperature is relatively stable and there is no need to adjust the humidity according to the temperature, the temperature control device can be removed; If the humidity requirements are not very strict (there is no control error ± 3% accuracy requirement), the humidity adjustment unit can be removed and replaced with a personnel using a hygrometer for measurement on a regular basis.

1.2 Characteristics of coating atomization humidification and dust removal system

Under normal circumstances, there are two commonly used methods of atomization dust removal and static electricity reduction in the workshop, one is high-pressure micro-humidification, and the other is dry atomization humidification. The reasonable selection of humidifier should be comprehensively considered from the aspects of humidification effect, equipment cost, operating cost, safety, control accuracy, power conditions (cold source, heat source, water source, air source, etc.), so as to meet the humidification requirements without causing waste, in line with the basic concept of modern production. Considering the need to prevent static electricity in the painting workshop and ensure an absolutely clean environment, dry atomization humidification systems are usually used. The dry atomization humidification system has the following characteristics: uniform and stable humidification, no water droplets, no bacteria, high humidification accuracy, and accuracy can meet the requirements of ±3%. The dry atomization humidification generator has the following significant characteristics: 1) small size, high humidification performance, and can avoid wetland phenomenon; 2) Easy and fast disassembly, easy maintenance and long service life; 3) Use ultra-small water storage tanks that are not easy for bacteria to breed; 4) It adopts a non-clogging nozzle, gas powered and adjustable pressure; 5) Optional temperature and humidity automatic control sensor to achieve automatic humidification and cooling according to the actual situation on site

Function.

Based on the characteristics of dry atomization humidifiers, it can be seen that the dry atomization humidification system has a smaller particle size and higher efficiency than the traditional high-pressure atomization humidification system, and because the dry atomization humidification system does not rely on high pressure, it reduces the wear and tear on the high-pressure pump, and is more safe and popular. At the same time, compared with the traditional high-pressure spray system is highly dependent on water quality, the dry atomization humidification system only needs to be filtered to use suitable water quality to achieve the effect of nozzle not clogging, no dripping and good atomization.

2 Design and analysis of atomization humidification and dust removal process scheme

2.1 Increase the selection of atomization area

Our company's painting workshop adopts water-based color paint, 2K varnish without middle coating B1B2 process, and its post-electrophoresis process is: manual gluing→UBS→PVC→ glue baking room→ED polishing→ blowing clean →B0→B1B2→ flash drying→ varnish→ top coat baking room→ inspection and polishing→ minor repairs→ delivery.

Although there is a blowing and cleaning post before the top coat spraying, there are still particle defects in the body, in response to this problem, after the actual station sections on the site are eliminated one by one, it is found that there are problems in the process of electrophoresis polishing to entering the blowing and cleaning post. Although dust has been removed by laying film on the dust wall and floor and applying petroleum jelly to the dust wall, dust and fibers are still present in the air in this area, exceeding the standard requirement (> 5 μm particles or fiber quantity requirement < 5), detailed summary information is shown in Table 1.

2.2 Calculation of humidification amount in atomized humidification area

The winter dry bulb temperature in Shenzhen Guanlan area is 5 °C, the relative humidity is 70%, the temperature in the workshop is set to 24 °C, and the relative humidity is 65%. The theoretical air change times in the area to be renovated in problem area 1 and problem area 2 are 1.5 times/h (actual between 1.0 ~ 2.0 times/h), and the air curve is calculated to increase 0.008 3 g/kg (dry air) per m3 of air, and the relative humidity of the workshop can reach 65%.

Taking the right part of problem area No. 1 as an example, the amount of atomization humidification required for this area is calculated as: Q1 = volume of the area to be humidified on the right (V1) × air density (ρ) × number of air changes per unit hour (n) × unit volume (V0) × air density (ρ) + maximum humidity surplus (the safety factor is usually 50% to satisfy). The air density ρ=1.180 kg/m3 and the maximum humidity surplus=50%×Q1 were calculated by the enthalpy diagram. Bringing the data into the above formula, it is obtained that Q1=41.94 kg/h, and the atomization humidification capacity of the other three areas is calculated in turn as Q2=29.05 kg/h, Q3=26.21 kg/h, Q4=32.76 kg/h, then the total humidification capacity of area 1 and area 2 is: Q total = Q1 + Q2 + Q3 + Q4 = 129.96 kg/h.

2.3 Calculation and selection of the number of atomization and humidification sprinklers

Painting workshops usually have enough compressed air and pure water, so the first thing that comes to mind should be a two-fluid humidifier. Compared with ultrasonic atomization humidifiers, two-fluid humidifiers are safer and more energy-saving. The two-fluid humidifier works on the principle of vacuum siphon to generate an ultra-fine mist of a two-stage atomization system. In fact, pure water and compressed air are sent to the control box for pressure regulation treatment and then sprayed out with a special nozzle to make the water atomization achieve the purpose of humidification. Table 2 summarizes the information of the two-fluid atomization humidifier selected by our company's workshop (the atomization spraying data in the table is measured when the compressed air pressure is 0.3 MPa and the water pressure is 0.1 MPa, which is consistent with the actual process conditions).

The number of atomization humidification nozzles required is calculated based on the AE-4(03C) material information and the information on adding atomization humidification area.

The number of atomization nozzles (N) = total humidification volume of regional demand (total Q) / atomization capacity of a single sprinkler (Q), and the data is brought in: N = total Q / Q = 129.96 / 7.2 = 18 pieces.

3 Material requirements and later maintenance of atomization and humidification equipment

3.1 Requirements for atomization humidification spraying equipment and materials

Due to the special nature of the coating operation, silicones must be strictly prohibited in all equipment and related supporting materials used. In addition, since the two-fluid atomization spray needs to be connected with pure water and compressed air, in order to strictly control the quality and prevent quality defects such as body shrinkage, it is recommended to add a filter to the pure water pipeline and an oil-water separator and filter to the compressed air pipeline.

The material selection for the atomization humidification system is mainly carried out from the aspects of preventing the appearance of body paint quality defects and humidity control accuracy, which can be referred to Table 3 for details.

3.2 Troubleshooting and maintenance methods

It is recommended to clean the filter once a month or in a shorter time period, and the rest such as compressed air pipelines or pure water transmission pipelines are recommended to be inspected at least once a week to see if there is a leakage problem, and if a leak is found, it should be stopped immediately. In the actual use process, there may be problems such as atomization nozzle not dispensing, small spraying range, and dripping. Using the idea of FMEA, the possible disappearance modes and failure causes are analyzed and the recommended measures are listed, as detailed in Table 4.

4 Conclusion

This paper introduces the atomization humidification spraying system in the coating workshop from the aspects of atomization area selection, equipment and material selection and precautions, and shows the related process and equipment planning matters, including atomization humidification amount, atomization nozzle number, construction precautions and later equipment maintenance, etc., and makes a relatively complete analysis and exposition of the entire process planning and equipment selection of the coating atomization humidification spraying system.

The atomization humidification spray dust removal system is expected to effectively reduce the number of particles in the process of electrophoresis polishing to topcoat blowing in the painting workshop, and the atomization dust removal spraying system has been officially put into use, due to the implementation and application of the atomization humidification project, the FTT (one-time passability) of the off-line production line in the painting workshop due to body particles has increased by about 50%, which is fully in line with the expected quality goals.