How to solve the problem of floating sludge in the secondary sedimentation tank?

- Release date: 2025-11-20 15:42:38

- Author: 鸿泰华瑞

- Reading: 809

- Keywords: Sludge floating in secondary sedimentation tank

At the same time, a certain concentration of reflux sludge or a certain amount of treated water should be provided for the biological treatment facility, so the working performance of the secondary sedimentation tank is directly related to the operation effect of the activated sludge system. The floating sludge phenomenon of the second sedimentation tank is common in urban sewage treatment plants and industrial wastewater treatment stations, which affects the image of sewage treatment, resulting in an increase in effluent SS, which will seriously lead to excessive effluent standards.

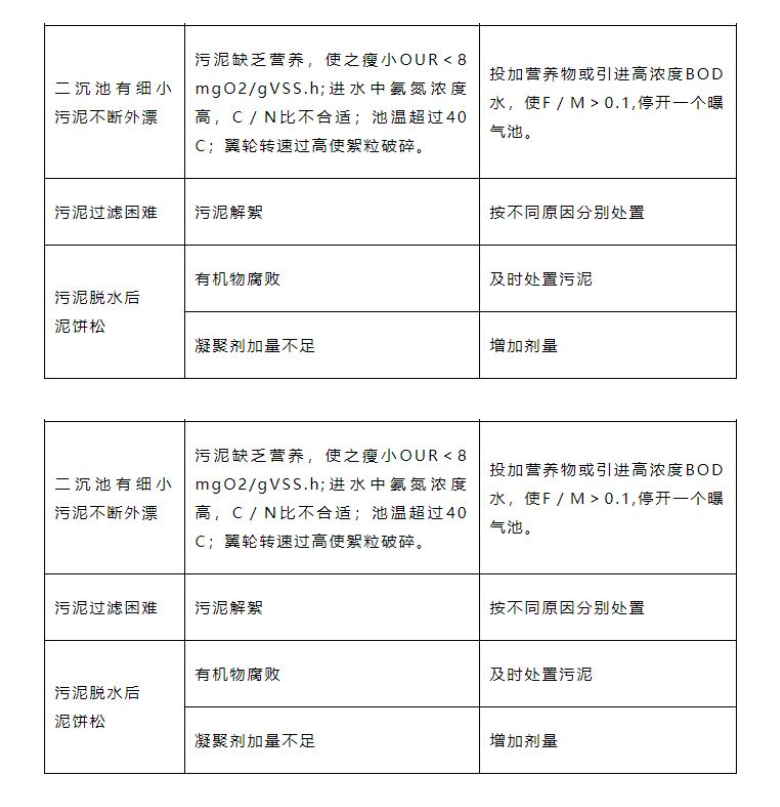

1. Floating up the lump sludge

The sedimentation pond is intermittently seen with fist-sized sludge floating up. There are two situations that cause large sludge to float:

1. Denitrification

The color of the floating sludge is lighter, sometimes rusty. The reason is that the nitrification degree in the aeration tank is high, the nitrogen-containing compounds are converted into nitrate by ammonia and nitrification, and the concentration of NO3-N is high.

The improvement method is to increase the reflux ratio, renew the sludge in the sedimentation tank, reduce the mud layer of the sedimentation tank, reduce the mud age, discharge more mud to reduce the sludge concentration, and appropriately reduce the DO level of the aeration tank. These measures reduce nitrification to reduce the source of nitrate.

2. Corrupt sludge

It differs from denitrifying sludge in that the sludge is dark in color and uses a strong foul odor. The reason for the occurrence is that the secondary sedimentation tank has dead corners and causes mud accumulation, which will become anaerobic and decay over a long time, producing H2S, CO2, H2 and other gases, and finally causing the sludge to float upwards.

2. There are many reasons for the mud in the sedimentation tank: first, because the return flow is too small, the mud scraper is damaged and the mud scraper is scraped out of the school for a long time.

The removal method includes eliminating the mud accumulation in the dead corner area, such as frequently inflating the dead corner area with compressed air to increase the sludge backflow. For areas prone to mud accumulation, they should be improved in the design.

2. Small particles of sludge float up

Small particles of sludge are constantly brought out with the water, commonly known as mud drifting. The causes of mud drifting can be roughly as follows:

1. The biological system treatment load (water volume and concentration) becomes larger, and mud can run, mostly because after the water volume increases, the residence time of the secondary sedimentation tank is shortened, and the activated sludge flows out of the secondary sedimentation tank before it has time to settle, resulting in mud running. At the same time, the increase in influent concentration will lead to the enhancement of activated sludge activity, which is not conducive to sedimentation. The water is turbid and muddy.

2. The filamentous fungus expansion sludge will produce mud running phenomenon before it settles.

3. Too low load operation, after the sludge is aged, the microorganisms oxidize themselves and dissolve the flocculent. It will also produce mud.

4. Low temperature, excessive aeration, excessive PH change, toxic and inert substances entering the biological system, etc., will also produce mud.

5. Influent water quality. Such as mutations such as PH and poisons, toxic and inert substances entering biological systems, etc., will also produce mud running.

6. The sludge is aged due to lack of nutrition or excessive oxygenation.

7. The ammonia nitrogen in the influent is too high and the C/N is low, which makes the colloidal mechanism of the sludge disintegrate and dissolve the flocculent.

8. The pool temperature is too high, often exceeding 40 degrees

9. The rotation speed of the mechanical aeration wing wheel is too high, causing the floc to break.

10. Low dissolved oxygen, high water load of sludge, incomplete digestion of organic matter, turbidity and dark color of the effluent.

11. Dissolved oxygen is continuously high. The low inlet load can easily cause the sludge to have light oxides and make it difficult to settle, and the light sludge floats out with the effluent.

The solution is to clarify the cause and treat it separately. The entry of toxic wastewater should be stopped when sludge is poisoned; For lack of nutrition, sludge aging and flocculating sludge must be properly supplemented with nutrients and rejuvenation measures should be taken.

3. Countermeasures for the sludge upscaling of the second sedimentation tank