What are the process characteristics of the winery sewage treatment equipment?

- Release date: 2025-11-20 16:02:39

- Author: 鸿泰华瑞

- Reading: 527

- Keywords: Winery sewage treatment equipment

How to treat the sewage generated by the distillery

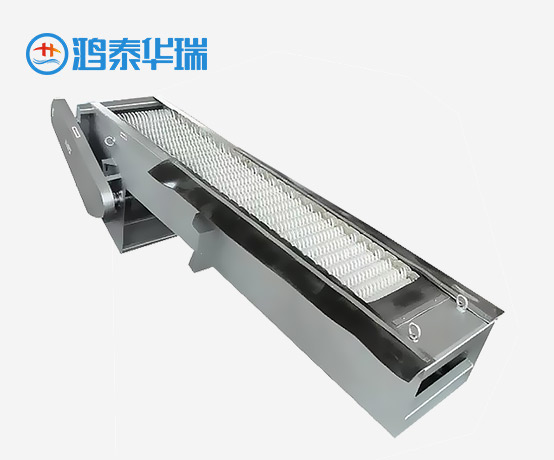

The liquor wastewater is collected by the workshop drainage pipe and then flows into the primary sedimentation tank outside the workshop, and flows to the conditioning tank after removing the lees and large particles suspended matter through the action of the grille and primary sedimentation, balancing the water quality and quantity.

The effluent of the regulating tank is lifted by the lift pump to coagulation and precipitation All-in-one equipment The adsorption and coagulation of the coagulant are used to remove fine suspended solids and colloidal particles in the wastewater, and the total phosphorus in the wastewater is removed, and the pH value of the wastewater is adjusted to 7.5~8.0 to meet the requirements of subsequent biochemical treatment, especially to ensure the alkalinity required for anaerobic reaction. The effluent from the coagulation sedimentation tank flows to the ABR anaerobic tank, and the anaerobic bacteria are used to degrade the organic matter to reduce the treatment load of the subsequent process of the system, and some pathogenic bacteria are killed by anaerobic fermentation.

The effluent from the ABR anaerobic tank flows into the anoxic tank for treatment, and the anoxic tank mixes and reacts with the slurry-water mixture flowing back into the internal circulation to play the role of denitrification and denitrification. Subsequently, it enters the contact oxidation tank, and the aerobic microorganisms use the oxygen provided by the outside world to further decompose the organic pollutants in the sewage, one part is used to synthesize the microorganisms' own structure to form sludge, and the other part is decomposed by aerobic microorganisms into CO2 and H2O, which are released into the atmosphere, and the organic pollutants in the water are removed in large quantities in the aerobic stage. In the MBR tank, the sewage can be discharged to meet the discharge standard after entering the clean water tank after being separated by slurry.

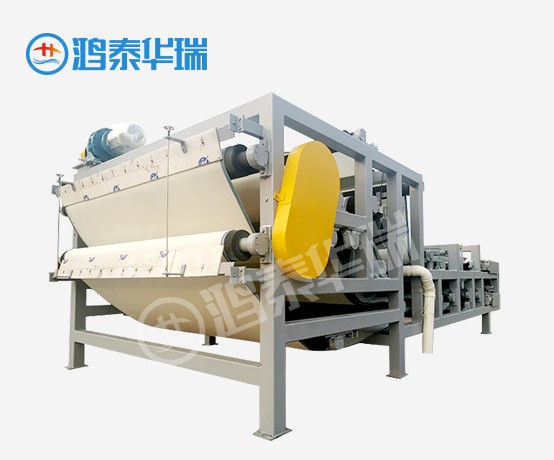

The physical and chemical sludge and remaining sludge generated by the system are discharged into the sludge concentration tank, and the sludge moisture content is regularly reduced by the box filter press, and the supernatant of the sludge concentration tank and the filtrate of the box filter press are returned to the conditioning tank for treatment. Mud cakes are transported for sanitary landfill disposal.

Process characteristics of sewage treatment equipment in wineries:

(1) The process is simple, no need to add carbon source, use raw sewage as the carbon source, and the construction and operation cost is low;

(2) Denitrification is in the front, nitrification is in the back, and the internal circulation is set up, and the organic substrate of the original sewage is used as the carbon source, the effect is good, the denitrification reaction is sufficient, and the nitrogen and phosphorus removal effect is good;

(3) The aerobic pool is behind, so that organic matter and denitrification residues are further removed, and the quality of hello water is improved.