A waste acid treatment system should be set up in the smelting flue gas acid production unit to produce neutralized water (called chemical water) by neutralizing waste acid and acidic wastewater discharged from open roads. The recycling of water resources in the chemical industry can not only reduce the cost of pollutant discharge, but also reduce the consumption of new water. It has good economic and environmental benefits.

1. Pollution process of smelting flue gas to produce acid

The flue gas purification process can be divided into three parts: purification, dry absorption and transformation. During the purification process, arsenic, dust, fog and other impurities are removed to meet the quality requirements of flue gas acid production. The principle of drying is to purify the water in the flue gas, then convert it through a catalyst, and then use dilute acid washing for absorption to produce concentrated sulfuric acid products. The process of flue gas acid pollution is as follows:

(1) The smelting flue gas contains high concentrations of sulfur dioxide and heavy metals, and the concentration of pollutants is significantly reduced after acid production.

(2) The main wastewater in flue gas comes from acidic wastewater generated during the purification process, such as sulfuric acid and sulfuric acid. Acidic wastewater is subject to certain procedures to meet standards, and is eventually discharged or used for recycling. The acidic wastewater discharged from the gas-acid system of the same type of smelter has the same water quality and the types of pollutants are basically the same.

(3) Solid waste includes sludge, waste residue, and waste catalyst in the process of waste acid treatment in the process of transformation. Waste catalysts have been discharged for many years, and the amount of waste catalysts is small. Depending on the treatment process, the amount and composition of sludge and sludge are different.

2. Pollution control of smelting flue gas acid production projects

2.1 Dirty acid treatment methods

At present, the key difficulty in smelting pyrite and flue gas is the treatment of sulfuric acid and sulfuric acid wastewater. On the other hand, technical and economic constraints have prevented the acquisition of suitable methods. The current lime method, lime salt method, ion exchange method, etc. are the main means of acid wastewater treatment. In addition, wastewater containing heavy metal ions such as arsenic and fluorine is generally treated by adopting a multi-stage combination method.

2.1.1 Lime method

When the environment is wastewater, lime reacts with pollutants such as arsenic to form precipitates such as calcium arsenite and calcium arsenite, which are then removed. Calcium arsenate and calcium arsenate have high solubility in water, slow precipitation, and the concentration of arsenic in drainage is greater than 0.5mg/l.

2.1.2 Lime-iron salt method

The addition of lime lactic acid wastewater adjusts the pH value, and the addition of polyvalent metal salts and polyvalent metals will produce insoluble (such as iron, zinc and aluminum) arsenic. Because sulfuric acid plant wastewater contains more iron salts, arsenic and arsenate produced at the same pH are lower than other metals such as arsenite and arsenate. Lime is also an inexpensive and easy-to-use pH adjuster. At present, the application of lime iron salt method is the most common.

2.1.3 Vulcanization method

Arsenic in sulfuric acid plant wastewater is produced by the precipitation reaction of insoluble arsenic trisulfide, which removes arsenic from the wastewater. This method also removes various metal ions from wastewater. In order to completely change the precipitation of arsenic trisulfide, we need to increase the excess of sulfide (0.2~1 times the theoretical content), as well as the excess sulfide to produce hydrogen sulfide under acidic conditions. If there is a hydrogen sulfide leak, it will pollute the environment. In order to consider effective hydrogen sulfide recovery measures, the process is more complex.

2.1.4 Adsorption and ion exchange methods

It is used to treat arsenic-containing wastewater. Due to the small amount of arsenic adsorption and trading of commonly used adsorption or ion exchangers (such as activated carbon, frogstone, ion exchange resin), the adsorption ion exchange method for sulfuric acid production wastewater treatment is still in the exploratory stage, and only cheap adsorbents or ion exchangers can be widely used.

2.2 Typical governance plan process and effect

2.2.1 Pretreatment of dirty acid

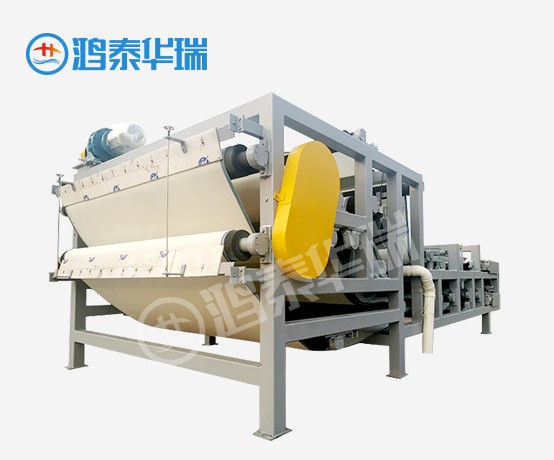

The waste acid generated by the sulfuric acid purification system is first gravitationally settled with a thickener, and the lead insoluble substance is introduced into the lead filter residue, and the lead removal rate is close to 100%. After neutralizing the reaction tank, it leads to the filtration removal and addition of pre-configured limestone slurry to produce gypsum, most of which is sulfuric acid neutralizes waste acid, and after adding sodium sulfide solution to the curing reaction tank in the neutralization filtrate, the removal rate of harmful heavy metals such as waste acid and sulfide precipitated arsenic is about 98% of the liquid sewage treatment after curing.

2.2.2 Sewage treatment

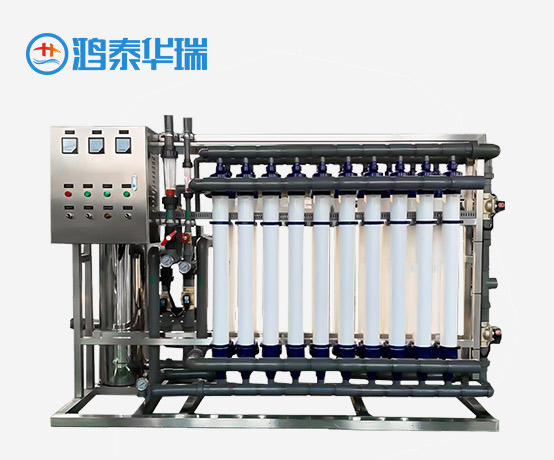

The water in the equilibration tank needs to be further adjusted by adding the pretreated waste acid, etc., and then sent to the lime emulsion neutralization and aeration tank, the pH value reaches 8.5, according to the arsenic content FeCl3 is added, and then the heavy metals and arsenic in the sewage are aerated for 90~120min, sulfur and Ca(OH)2, FeSO4, reaction, metal hydroxides form calcium arsenate, calcium arsenate solid particles and suspension. It is then sent to the Gore membrane filter, where the liquid filter bag enters the filtration chamber through the membrane and flows out of the overflow to meet environmental emission standards for smelting or greening. Solid particles become clogged through membrane bags on the surface of the membrane. When the thickness reaches a certain level, the filter automatically enters the post-cleaning state, and the filter slag quickly descends from the membrane surface to the bottom of the filter cone. When the bottom of the cone accumulates to a certain amount, the bottom valve opens automatically and the slag enters the sludge tank. Gore membrane filter feeding, filtration, cleaning prevention and slag removal process. The water content of the Gore membrane filter residue is 85~95%. It requires the use of a pressure filter to further remove the water. After filtration, production and transportation, there will be no two contaminations. The filtrate returns to the neutralization tank.

3. Environmental impact of smelting flue gas acid production projects

3.1 Exhaust gases

Only in the process of smelting soot and dust emissions, the high concentration of SO2 flue gas is directly discharged, resulting in high concentrations of ambient air pollutants, and the formation of acid mist will have adverse effects on human health. According to the measured data, the concentration of acid and sulfuric acid mist in the exhaust gas has little impact on the environmental quality of the regional atmosphere, and sulfuric acid is produced in the two transfer and absorption processes after purification, and the dust is emitted after purification.

3.2 Dirty acid

Acid wastewater is the most important source of pollution in smelting flue gas to produce acid. After the "lime emulsion neutralization iron aeration dearsenic Gore membrane filtration process" or as supplementary water wastewater treatment, the lime emulsion configuration sewage purification process will be carried out beyond the internal circulation of the line and will not adversely affect the external environment, water and soil environmental quality. In addition, the smelting flue gas acid engineering project is mainly solid waste sludge, waste residue waste acid, the production process includes gypsum, slag, steel slag, sulfur and lead filter cake, in addition to other hazardous waste gypsum, which needs to be delivered or sent to the hazardous waste disposal center in time by qualified units to avoid environmental pollution factories and nearby areas.

4. Comprehensive discussion

With increasing attention to environmental protection and stricter formulation and implementation of pollutant emission standards, many smelting enterprises have also taken flue gas acid production as a necessary first choice. Although acid gas itself is a pollution control project, controlling and treating pollutants such as waste acid and other pollutants, and further reducing the impact on the environment, is something we must consider and address.