Waste gas emissions from the textile printing and dyeing industry account for a large proportion and are highly polluting. How to deal with it has become the focus of environmental protection attention?

- Release date: 2025-11-20 14:55:26

- Author: 鸿泰华瑞

- Reading: 791

- Keywords: Textile printing and dyeing, exhaust emissions, strong pollution, how to deal with it, environmental protection concerns

our country is a big textile country, the textile industry is generally concentrated in Jiangsu, Zhejiang, Fujian, Guangdong, Shandong five coastal provinces, this industry has driven the national economy, improved people's living standards, brought us a series of development contributions while also causing great pollution to the atmospheric ecological environment.

There are many industries involved in VOCs emissions from industrial sources, accounting for as much as 55.5%, and the key industrial industries in industrial sources include petroleum refining and storage and transportation, chemical industry, solvent use (including surface coating), etc. VOCs from solvent use accounted for 23.3% of total emissions. The textile printing and dyeing industry uses a large amount of organic solvents in the production process, which is an important component of VOCs emissions from industrial sources, accounting for about 2.8% of the total emissions.

Volatile organic compounds have been included in the main pollutants in the "Air Pollutant Emission Standards for Textile Industry", and the waste gas treatment in the textile industry has changed from the original treatable to a must-treat item.

Sources of exhaust gas in the textile printing and dyeing industry

The textile printing and dyeing production process is roughly divided into four stages: cloth preparation and pretreatment, dyeing, printing, finishing and finished product packaging. Due to the difference in processing fabrics, the process is slightly different, and a variety of raw materials are often required to be produced through multiple combined processes.

The exhaust gas of the printing and dyeing industry mainly comes from two aspects: one is the spinning process of chemical fiber, and the other is the textile pretreatment and functional post-treatment finishing process.

Taking the spinning process of viscose fiber chemical fiber as an example, the raw materials need to be made into spinning liquid first, and in the process of manufacturing spinning liquid, a large amount of carbon disulfide needs to be added, so the spinning process will release harmful gases mainly hydrogen sulfide, carbon disulfide and sulfur dioxide.

Heat setting machine treatment is an important part of the textile pretreatment process. During heat setting, various dye additives and coating additives on the textile will be released, so a large amount of VOCs (organic volatiles) will be released at the final exhaust port. These gases are mainly some organic gases such as formaldehyde, polybenzene, and aromatic hydrocarbons.

In the process of functional finishing of textiles, the iron-free and flame-retardant finishing of cotton fabrics must go through the baking process, due to the addition of some chemical additives, formaldehyde and other aldehyde gases and ammonia will appear during baking.

In summary, the printing and dyeing industry, as a key source of VOCs (volatile organic compounds) from industrial sources, also has a lot to do with PM2.5. It has been reported that VOCs emissions in our country's textile printing and dyeing industry account for 8.8% of the total VOCs emissions from different sources and more than 30% of VOCs emissions in industrial processes.

Characteristics and hazards of printing and dyeing exhaust gas

Before and after printing and dyeing processes, forming machines, roasting machines, roasting machines, burning machines, grinding machines and other processing processes of fabrics, various dye additives and coating additives will be released in the form of organic gases such as formaldehyde, polybenzene, aromatic hydrocarbons, etc. How to effectively control and deal with this volatile organic compound is an urgent problem faced by printing and dyeing sites.

Secondary glass fiber filtration device: The air inlet of the exhaust gas treatment equipment is equipped with a secondary glass fiber filtration device to control dust emissions.

Harmful substances in exhaust gas mainly include: carbon disulfide, hydrogen sulfide, methyl benzene, formaldehyde, polybenzene, aromatic hydrocarbons, etc.!

Humans breathe the harmful gases of textile printing and dyeing factories for a long time, which can easily produce various diseases: leukemia, stomach problems, respiratory infections, drowsiness, irritability, chest tightness, weakened immunity, etc. In particular, weakened immunity is easily invaded by viruses and bacteria!

Some of these toxic and harmful gases are very easy to cause catastrophic accidents such as fires, explosions and poisoning of workers in the factory area, and workers are also prone to occupational diseases if they work for a long time when toxic and harmful gases exceed the standard.

The toxic and harmful gas emissions in the printing and dyeing industry are relatively hidden, difficult to supervise, and extremely harmful, so it is very important to do a good job in monitoring toxic and harmful gases.

A convenient and reliable way to detect toxic and harmful gas concentrations is to install gas detection alarms. The gas detection alarm can monitor the gas concentration in real time, and when the preset value is exceeded, the alarm will immediately issue an audible and visual alarm signal or link the exhaust device.

Waste gas treatment methods in the printing and dyeing industry

The high-temperature plasma incineration treatment scheme is suitable for:

Substances with high VOCs content, complex composition, flammable and explosive, and difficult to decompose, containing a small amount of particulate matter, oily matter, and continuous large-dose emission of industrial waste gas.

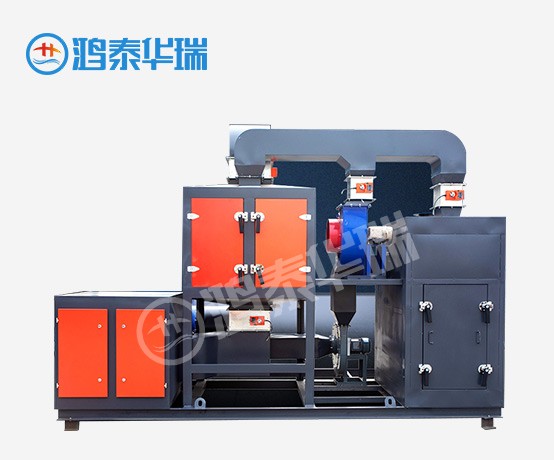

High Temperature Plasma Incineration Technology:

High-temperature plasma incineration technology is the collective discharge of high-frequency (30KHz), high-voltage (100,000 volts) high-power power supply under specific conditions. The industrial waste gas rises sharply from normal temperature to 3,000 degrees Celsius in the reactor, and under the dual action of high temperature and high potential, organic pollutants (VOCs) are instantly ionized and completely cracked. After high-temperature plasma incineration treatment, organic matter (VOCs) in industrial waste gas are cracked into carbon, carbon dioxide, water vapor and other elemental substances.

Features of high-temperature plasma incineration equipment:

The powerful power and professional design make the industrial exhaust gas instantly become 3,000 degrees high-temperature plasma, and the removal rate of harmful substances is greater than 98%, which meets the national designated emission standards. Stainless steel integrated structure, corrosion resistance, safe and reliable intelligent remote control, no full-time personnel on duty.

The "high-temperature plasma incineration" technology has the following advantages over the "traditional RTO (natural gas incineration method)":

1. Continuous and uninterrupted treatment of exhaust gas, (natural gas RTO is intermittent working mode), which is particularly important in the application of waste incineration exhaust gas and gravure printing organic waste gas treatment.

2. Broad spectrum: It can treat industrial waste gas with high concentration, complex composition, flammable and explosive, and contains a lot of moisture, solid and oily substances, and achieve standard discharge.

3. No natural gas consumption and no carbon emission problem. There are no moving parts such as valves, and it can run for tens of thousands of hours without failure.

4. Small wind resistance and low energy consumption: To handle a gas RTO of 20,000 cubic meters per hour, an induced fan with a power consumption of 90 kW is required to overcome the wind resistance of the ceramic heat regener. The high-temperature plasma incineration equipment (25 kW) that handles 20,000 cubic meters per hour consumes only 46 kW of power together with the draft fan (21 kW). When the emission concentration of VOCs exhaust gas is less than 200mg/m3, the power consumption per 10,000 m3 is only 10kW per 10,000 m3. In terms of capital investment and operating costs, this scheme is far better than the concentration adsorption + RTO incineration scheme.

5. High energy efficiency ratio: save energy, high temperature plasma equipment exhaust gas outlet temperature, which is only a few tens of degrees higher than the exhaust gas inlet temperature.

6. Good treatment effect: dioxins and other difficult-to-treat substances can be completely decomposed in an instant to achieve standard discharge. (Ideal solution to the problem of dioxin emissions from waste incineration exhaust)

7. No ozone emission problem (ozone emission problem in low-temperature plasma equipment).

8. Economical: The price of high-temperature plasma equipment of the same specification is less than one-half of that of gas-fired RTO, and the operating cost is less than one-half.

9. Small footprint, high degree of automation, manpower saving, and low operating cost.

10. No secondary pollution. No peculiar smell is an important consideration for densely populated areas.

11. The cost of natural gas incineration RTO is high, consuming a large amount of natural gas and oxygen, increasing carbon dioxide and carbon monoxide emissions, and there are concerns about secondary pollution, which cannot cope with the increasingly strict environmental protection standards. Due to its working mechanism and structural defects, natural gas incineration method needs to consider explosion-proof issues in flammable and explosive places, or when treating exhaust gas containing combustible components. There may be safety issues caused by leaks during natural gas transmission and storage. The application of high-temperature plasma incineration technology in industrial waste gas treatment is an epoch-making technological change. High-temperature plasma incineration technology will gradually replace natural gas RTOs as an emerging industry.